Videos

Environmental testing completed for NASA James Webb telescope

Successful acoustic and sine-vibration testing ensures the composites-intensive space telescope will survive all of the harsh conditions associated with a rocket launch to space.

Watch3D-printed prefab homes aim to disrupt construction market

California startup Mighty Buildings’ award-winning prefabricated building production process relies on large-format 3D printing, UV-curable resins, digital design and automation.

WatchManna Laminates organosheet laminate aims for automotive crash applications

Formtex organosheets are ideal for the manufacturing of structural and semi-structural automotive parts with high energy absorption, high impact resistance and additional multi-axial reinforcement.

WatchNAWA Technologies develops U.S. subsidiary to extend VACNT application scope

NAWA America’s immediate focus is to bring NAWAStitch to mass market, a thin film containing trillions of VACNT arranged perpendicular to the carbon fiber layers to reinforce the weakest part of a composite.

WatchSamad Aerospace eVTOL aircraft completes successful flight test

The successful test ensured the all-electric e-Starling’s CTOL flight capabilities and achieved an essential step toward its VTOL aircraft development.

WatchWSU-NIAR receives $13.5 million from Air Force for advanced composites research

Additional funding extends NIAR’s Modeling for Affordable, Sustainable Composites (MASC) research program, which will develop technologies to optimize digital twin data.

WatchCFP Composites launches low-cost, carbon fiber laminate that processes like metal

The BM-5 laminate board can be screwed, tapped, fastened, bonded and painted just like a metal, and requires no prepreg, layout or curing. It also has a comparable cost to metal, removing operator and financial barriers to adopt carbon fiber.

WatchEpisode 35: Lisa Ketelsen, Covestro

CW Talks visits with Lisa Ketelsen, head of thermoplastic composites and CEO of Maezio at Covestro. Ketelsen talks about her path to Covestro and the Maezio product line, Maezio’s attributes and applications, and how she sees thermoplastic composites evolving in the marketplace.

ListenUniversity of Stuttgart, Institute of Aircraft Design uses adaptive mold technology from Adapa

Reconfigurable mold aids development of digitally-manufactured composite parts for reduced-emissions transport vehicles.

WatchRapid Robotics launches ready-to-work robotic machine operator

“Out of the box,” the Rapid Machine Operator — which automates common machine tasks for a variety of industries — can be up and running in hours, no systems integration required.

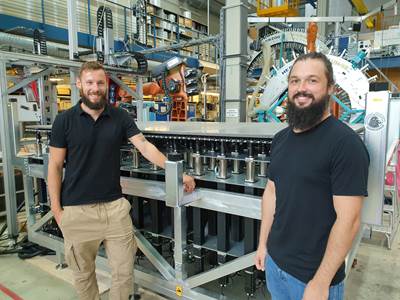

WatchAddcomposites installs AFP-XS at Compositadour and integrates humm3 flash lamp

French technology platform expands access to composites beyond aerospace, while humm3 offers cost-effective dry fiber and thermoplastic tape placement in addition to CF/epoxy prepregs.

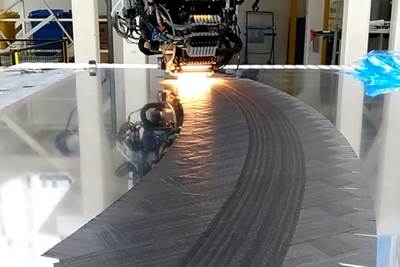

WatchAFP tow steering comes of age, Part 1: Current state

It used to be enough that AFP systems could precisely and quickly place and cut multiple tows to build complex aerostructures. Now, fabricators need those tows steered, and the tighter the radius, the better.

Watch