University of Stuttgart, Institute of Aircraft Design uses adaptive mold technology from Adapa

Reconfigurable mold aids development of digitally-manufactured composite parts for reduced-emissions transport vehicles.

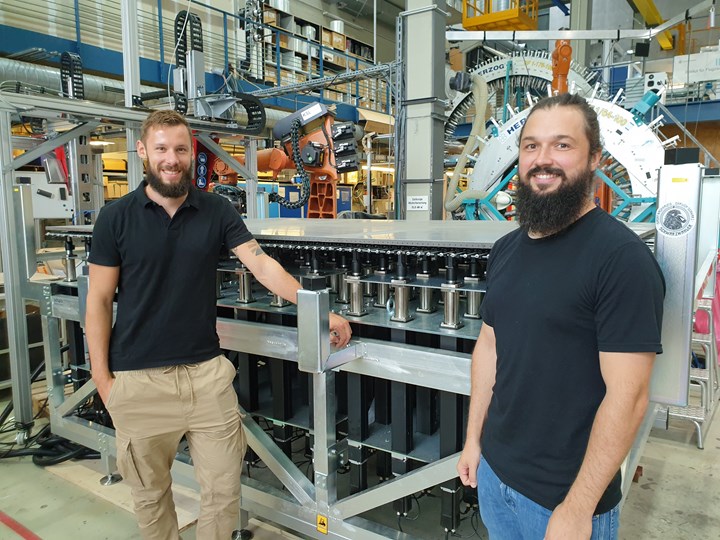

Florian Helber and Jörg Dittmann at University of Stuttgart are using an Adapa adaptive mold for developing carbon fiber composite parts using robotic manufacturing for the automotive industry. Photo Credit: University of Stuttgart, Institute of Aircraft Design

The (IFB, Stuttgart, Germany) has chosen an adaptive mold system from (Aalborg, Denmark) to develop an aerodynamic fairing for road transport vehicles. This composite part is manufactured using the Adapa reconfigurable tooling and collaborating robotic systems based on 3D digital design files.

This development is in cooperation with one of the leading manufacturers of transport vehicles and is aimed at reducing CO2 emissions on their vehicles. The reconfigurable adaptive mold technology will be used to reduce the cost of manufacturing unique designs, tailored to specific vehicles.

The University of Stuttgart IFB is applying their composites design and manufacturing expertise to develop materials and manufacture technologies that interact with predesigned production processes and yet still allow for flexibility in product design while reducing the carbon footprint, which is imperative. Adapa is proud to support this development and effort to improve global vehicle emissions.

Related Content

-

Industrializing additive manufacturing in the defense/aerospace sector

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

-

Otto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.