Welding

Collins Aerospace selected by AFRL to build thermoplastic composite fin for F-16

Part of $100 million, five-year investment to advance, qualify thermoplastic composites for military and commercial aero applications.

Read MoreThermoplastic composites welding: Process control, certification, crack arresters and surface prep

More widespread use of welded composite structures within a decade? Yes, but further developments are needed.

Read MoreThermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.

Read MoreCollins Aerospace demonstrates new thermoplastic composites capabilities

Collins Aerospace in Almere has produced a 7-meter raceway for the Clean Sky 2 MFFD lower fuselage using novel CCM and tooling technology while the Riverside facility in the U.S. advances AFP and welding as part of global strategy for more sustainable airframes.

Read MoreTwenco develops sensors for smart molds and process control in resin infusion and composites welding

Non-invasive DEA and NDT Analyzer for multi-parameter monitoring, QA and control, including real time simulation feed and 3D process visualization across and through composite parts.

WatchDaher, Luxembourg's LIST to develop welding technology for thermoplastic composite aircraft substructures

The agreement will focus on infrared welding technology to enable high-volume, automated manufacturing in aviation.

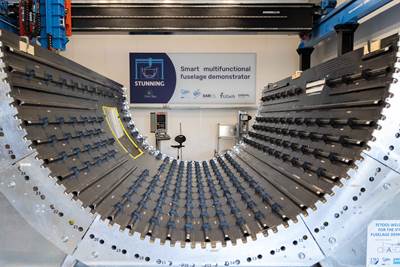

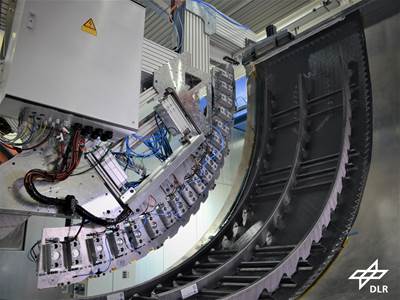

Read MoreDLR Augsburg integrates sixth frame to upper half fuselage test shell for MFFD

Clean Sky 2 thermoplastic composite demonstrator advances toward full assembly.

Read MoreDLR Institute of Structures and Design releases video on TB-Rumpf welded thermoplastic composites

Autoclave-free consolidation and resistance welding validated for future aircraft thermoplastic composite fuselage.

WatchPlant tour: Qarbon Aerospace, Milledgeville, Ga. and Red Oak, Texas

Veteran aerostructures Tier 1 transforms into 21st century leader in thermoplastic composites and multiple new markets.

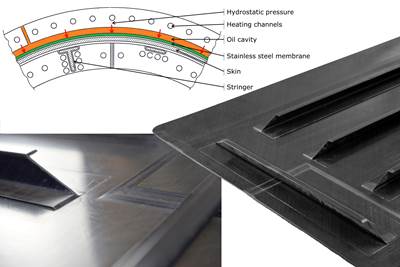

WatchHydrostatic membrane consolidation: Skin-stringer panels in 60 minutes

Airbus and Siempelkamp demonstrate press process as alternative to thermoplastic welding, aimed to enable rate 100 aircraft and future mobility manufacturing.

Read More