Thermoplastics

Plant tour: ATC Manufacturing, Post Falls, Idaho, U.S.

ATC is at the top of the list when it comes to thermoplastic composites and aerostructures manufacturing. CW explains why.

Read MoreCollins Aerospace acquires thermoplastic parts fabricator Dutch Thermoplastic Components

The acquisition underscores Collin’s commitment to deliver light, cost-efficient and sustainable aircraft structures.

Read MoreOribi Composites, Packard Performance partner for off-road powersports thermoplastic composite wheel

Composite UTV wheels are 50% lighter than aluminum and can handle extreme terrain and driving conditions.

Read MoreDOMMINIO virtual workshop to explore multifunctional and intelligent composite airframe parts

Nov. 30, 2021 event for H2020 project will review latest advances in thermoplastic composites, additive manufacturing and digital manufacturing.

Read MoreLingrove’s eco-friendly Ekoa composite materials target furnishings and interactive applications

Ekoa, comprised of plant-based fiber reinforcements and resins, achieves cosmetic, structural durability and elegance for a range of interior, furniture and transportation applications.

Read MoreSuprem launches continuous fiber-reinforced thermoplastic brand tailored to AM

Filaprem materials feature high quality, exceptional fiber/matrix distribution and low porosity.

Read MoreFraunhofer commissions automated Engel production cells for thermoplastic composite R&D

Fraunhofer PAZ pilot plant center installs v-duo 700 vertical machine and duo 900 injection molding machine to combine thermoplastic composite processes with a variety of injection molding technologies.

Read MoreNREL explores novel manufacturing approach for next-generation wind turbine blades

3D printing of thermoplastic blades enables thermal welding and improves recyclability, offering the potential to reduce turbine blade weight and cost by at least 10%, and production cycle time by 15%.

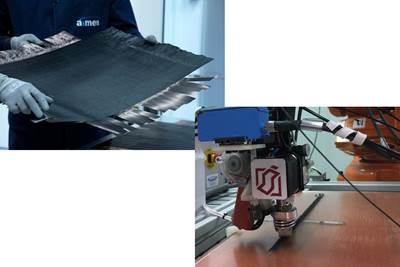

Read MoreAIM3D multi-material 3D printer targets precise, cost-effective polymer processing

Extrusion 3D printer offers considerably faster build rates and can print up to three different materials in parallel for metals, ceramics and high-temperature plastics such as PEEK and PPS with or without fiber filling.

Read MoreSAM|XL develops closed-loop manufacturing for composites

Collaborative R&D center at TU Delft develops sensor- and robot-based automation for Composites 4.0 manufacturing, including STUNNING project for welded assembly of a thermoplastic composite fuselage demonstrator.

Watch