Thermoplastics

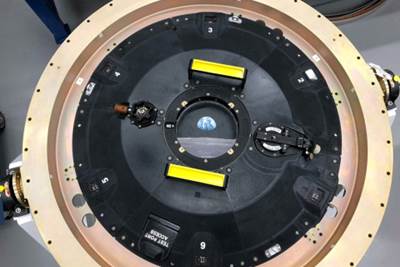

DLR Institute of Structures and Design releases video on TB-Rumpf welded thermoplastic composites

Autoclave-free consolidation and resistance welding validated for future aircraft thermoplastic composite fuselage.

WatchEconCore, Flaxco reveal flax fiber-reinforced thermoplastic honeycomb panels

Natural fiber sandwich panels are expected to replace those made from glass and carbon fiber, offering enhanced rigidity and sustainability for applications in automotive and sporting good markets.

Read MoreSafran joins the ThermoPlastic composites Research Center

The aerospace group joins as part of the ongoing initiative to decarbonize aviation. Safran believes thermoplastic technology development acceleration is a key target to meet this goal.

Read MoreStratasys collaborates with Lockheed to qualify composite materials for space, aviation end-use parts

Report made public by Metropolitan State University of Denver delivers qualification data for Antero 840CN03 for additively manufactured end-use parts requiring high thermal and chemical resistance, and ESD properties.

Read MorePlant tour: Qarbon Aerospace, Milledgeville, Ga. and Red Oak, Texas

Veteran aerostructures Tier 1 transforms into 21st century leader in thermoplastic composites and multiple new markets.

WatchBcomp, KTM Technologies brake cover listed as finalist for JEC Innovation Awards 2022

Flax fibers were used to reduce the CO2 emission of the motocross brake cover by 82%, with KTM’s Conexus for effective bonding between thermoset and thermoplastic parts.

Read MoreHypetex creates colored carbon fiber covers for IQOS tobacco heating devices

The U.K. manufacturer and supplier of advanced materials coordinated all aspects, from initial concept to final solution, including a fully optimized production process.

Read MoreLaboratory for Intelligent Lightweight Production at CTC Stade advances digital solutions for industrial composites

Four-year, 12-million-euro LaiLa project with Helmut Schmidt University combines R&D with industry collaboration to solve real production pain points, validate solutions in digital lab/model factory at CTC and transfer knowledge to supply chain including customized training.

Read MoreLanxess expands Tepex flowcore composite range

Focusing on lightweight components for cars, sports equipment and consumer goods, the long fiber-reinforced thermoplastic enhances ductility, recylability and processability.

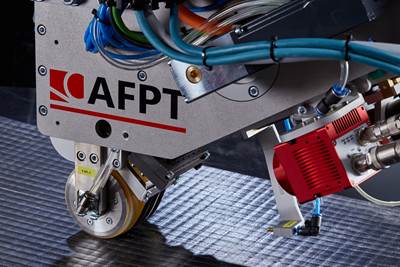

Read MoreAFPT GmbH expects to acquire composite tube manufacturer

Netherlands-based Alformet BV will enable AFPT to expand the use of tubular, fiber-reinforced thermoplastic structures across a wide range of end markets.

Read More