Thermoplastics

Tepex composite opens up new opportunities for electric skateboards

The continuous fiber-reinforced thermoplastic is used for a trough-shaped skateboard deck application, notable for its high torsional and bending strength, light weight and moisture protection.

Read MoreCygnet Texkimp thermoplastic lab line build supports composites innovation

Direct Melt Impregnation Thermoplastic Line to enable faster development of composites technology in automotive, aerospace, construction and energy markets through dedicated customer trials.

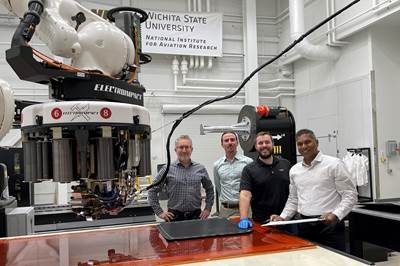

Read MoreNIAR-WSU, Victrex begin NCAMP materials and process qualification for AFP

In-depth investigation into AFP machine variability on composite allowables begins on carbon fiber-reinforced thermoplastic (CFRTP) test panels to achieve certification framework.

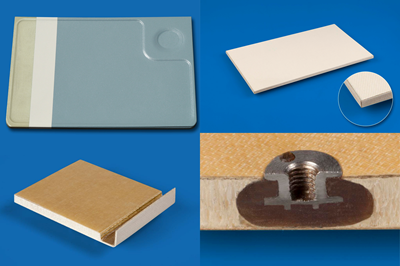

Read MoreFITS Air thermoplastic sandwich panels enable low-cost, low-weight, sustainable aircraft interiors

FITS Air and FITS Base sandwich panels provide alternative material avenues for aerospace and other industries, including low weight, low part production cost, thermoformability and recyclability.

Read MoreCFRTP E-bike frames enable repair and end-of-life repurposing

Under its Novel Composites E-Bike project, the NCC, with Starling Cycles and Composite Braiding, proved the use of thermoplastics for the production of electric mountain bicycle frames.

Read MoreOCSiAl launches graphene nanotube concentrate for high-quality thermoplastic auto parts

OCSiAL’s TUBALL MATRIX 822 graphene nanotube concentrate for PA, filled PPS, ABS, TPU and PC overcomes the necessity of separate operation lines when painting metallic and composite components.

Read MoreGKN Aerospace named supplier of all Gulfstream G800, G400 business jets

Workshare includes design and manufacture of sustainable, thermoplastic composite rudder, elevators and floorboards, as well as metal-bonded fuselage panels and machined wing skins.

Read MoreSuprem thermoplastic composites contribute to pressure vessel expansion

High-quality, high-performance UD thermoplastics are dedicated to industrializing recyclable Type III, IV and V pressure vessels.

Read MoreOffshore wind-to-hydrogen infrastructure development incorporates Strohm TCP, Siemens Gamesa electrolyzers

Concept for decentralized green hydrogen generation replaces power cables with subsea thermoplastic pipes to transport energy generation from turbine to shore.

Read MorePatent-pending welder rapidly melts thermoplastics

The FlatJet Welder, designed for thermoplastic components of all sizes, blasts a thin, directed jet of uniform, high-temperature air/gas for a fast, full-surface melt.

Read More