Resins

HX5 thermoplastic nanocomposite demonstrates electromagnetic shielding properties

Certified for use from rockets and satellites to amphibious transport vehicles, EMI testing indicates exceptional attenuation when bare or plated for shielding effectiveness.

Read MoreDynamic Modifiers introduces low-smoke, flame-retardant thermoplastic compound

Made for a wide range of markets, PAL...VersaCHAR addresses concerns surrounding traditional flame-retardant materials without sacrificing performance.

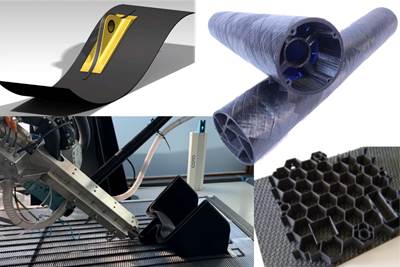

Read MoreClean Sky 2 IMCOLOR project develops integrated manufacturing process for lightweight product design

Multi-shot injection molding process and thermoplastic automated fiber placements with in-situ consolidation for automated, easy-to-reproduce parts that perform at high mechanical levels.

Read MoreInnovate UK grants NCC £355k to help achieve net zero future

Funding will investigate how composite materials can best be used in final products, mitigation of their environmental impact and overall sustainability.

Read MoreCarbon fiber windsurf fin incorporates Sicomin bio-based epoxy resin

Sicomin GreenPoxy 33 meets high-performance windsurfing fins requirements, accommodating significant loads, high torsion stiffness and flexibility.

Read MoreMultifunctional epoxy formulations show potential for future composite manufacturing

Study results from Swinburne University show highly increased cure time as well as reduced cure temperatures. Further research hopes to enable faster, higher-volume composites 3D printing and other processes.

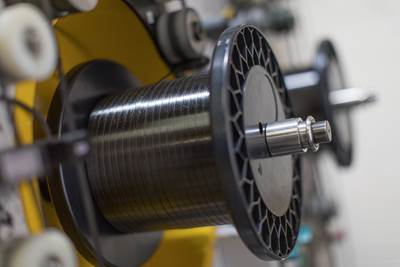

Read MoreSecured Innovate UK funding expands Bindatex tape slitting capabilities

Funding will ensure 1-millimeter thermoplastic UD slit tape volumes can meet growing demand for aircraft and other key transport applications.

Read MoreEpisode 35: Lisa Ketelsen, Covestro

CW Talks visits with Lisa Ketelsen, head of thermoplastic composites and CEO of Maezio at Covestro. Ketelsen talks about her path to Covestro and the Maezio product line, Maezio’s attributes and applications, and how she sees thermoplastic composites evolving in the marketplace.

ListenFuture composite manufacturing - AFP and Additive Manufacturing

TU Munich symposium explores how these technologies are merging and reviews R&D that is creating a path forward.

Read MoreNREL, Arkema research recyclable, thermoplastic composite wind turbine blades

The National Renewable Energy Laboratory and partners aim to develop more sustainable, longer-lasting turbine blades that are less expensive to manufacture.

Read More