Processes

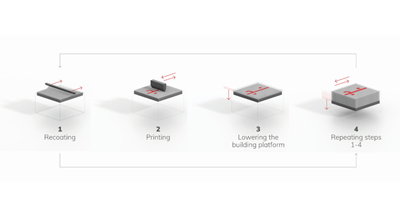

GE, Fraunhofer IGCV, Voxeljet to develop the world’s largest 3D printer for offshore wind applications

The partnership will streamline the production of key components of GE’s Haliade-X offshore wind turbine with the advance casting cell (ACC) sand binder jetting 3D printer.

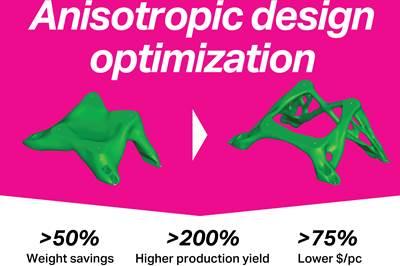

Read MoreCovestro and ParaMatters develop anisotropic optimization software for composites

Designers and engineers can use the new optimization tool to obtain the most optimal part design based on material deposition and fiber orientation.

WatchAnisoprint, Additive Flow launch full-scale topology optimization software for composites

Additive Flow’s FormFlow software enables users to optimize geometry smoothly through all phases of the design process. The tool is compatible with Anisoprint’s slicing software, Aura, for composite 3D printing.

Read MoreCorrosion-resistant resins enable FRP petrochemical plant equipment

Spanish fabricator Ollearis used AOC resins and glass fiber filament winding to meet design and cost requirements for combustion unit tank and pipes.

Read MoreImpossible Object offers high-performance, PEEK 3D-printed products at PA12 prices

Combination of the company’s proprietary CBAM process and lower cost source saves customers up to 80% and offers stronger, better performing products.

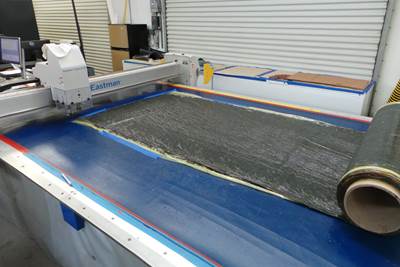

Read MorePrecision Cutting Enables High Speed Composites Molding Process

Automatic cutting of proprietary composite materials is critical for high speed molding of military-grade pressurized camera enclosures.

Read MoreMarkforged launches software to scale additive manufacturing

Called Eiger Fleet, new cloud-based software enables more control and automation in connection with Markforged 3D printers.

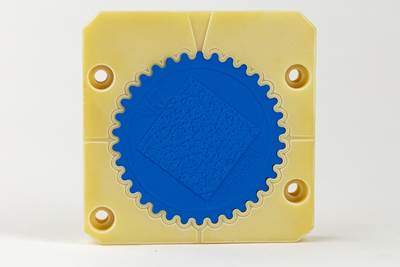

Read MoreEnvisionTEC, Covestro collaborate on material, printer solutions for DLP 3D printing tooling applications

Covestro DLP resin e-PerFORM used with EnvisionTEC’s Perfactory P4K series DLP 3D printing demonstrates faster, more cost-effective print speeds for the production of injection molding tooling.

Read MoreB9Creations' 3D printer uses Mechnano's nanomaterials

This partnership brings together B9Creations’ B9 Core Series 3D printers and Mechnano’s nanomaterials functionalized with carbon nanotubes, which improve impact, tear resistance and tensile performance.

Read MoreNotus Composites launches low-temperature curing epoxy prepreg

NE7 formulation enables composite manufacturers to cure components at temperatures as low as 70ËšC, reducing energy consumption and enabling more cost-effective tooling options.

Read More