Notus Composites launches low-temperature curing epoxy prepreg

NE7 formulation enables composite manufacturers to cure components at temperatures as low as 70ËšC, reducing energy consumption and enabling more cost-effective tooling options.

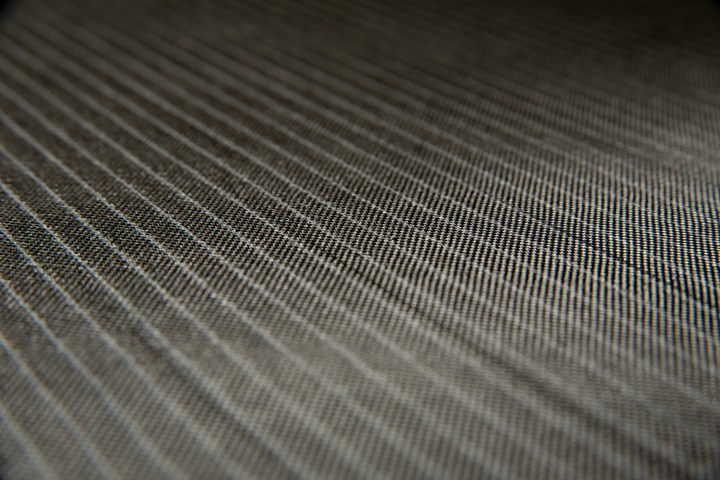

Notus NE7 low-temperature curing prepreg. Photo Credit: Notus Composites

(Ras Al Khaimah, United Arab Emirates), a producer of epoxy prepreg materials, has launched its new NE7 low-temperature curing prepreg system. The new Notus NE7 formulation reportedly enables composite manufacturers to cure components at temperatures as low as 70ËšC, reducing energy consumption and enabling more cost-effective tooling options.

Notus Composites has developed the new NE7 prepreg systems for applications across the marine, architecture, industrial and wind energy sectors. Existing prepreg manufacturers can now use more cost-effective composite tooling, with new prepreg users able to switch easily from existing infusion or wet laminating processes without creating new, expensive high-temperature tooling.

A deck for a racing yacht, which uses NE7 woven and multiaxial carbon fibre prepregs. Photo Credit: Notus Composites

According to Notus Composites, NE7 prepregs can be cured at temperatures as low as 70ËšC, with the standard cure cycle being 12 hours at 70ËšC, matching the typical cycle time for an infused part with a component Tg of 85ËšC. NE7 materials reportedly have a good outlife of 30 days at 20ËšC and are available in all prepreg and Notus single-sided N1-Preg formats with unidirectional (UD), multiaxial and woven reinforcements. NE7 can also be supplied as a resin film.

Notus Composites’ EPFR-609 FR prepreg materials (tested and certified to NFPA 285, ASTM E84 and EN13501-1) are now available with the NE7 low-temperature curing technology, combining additional processing options with leading fire performance.

Related Content

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

-

Cutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

-

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.