Corrosion-resistant resins, filament-wound fiberglass composites and creative design engineering were key to Ollearis’ work on several large petrochemical plant components for a SABIC subsidiary facility. The components are shown here prior to shipment and installation.

Photo Credit, all images: AOC

Composite materials are known for their durability in highly corrosive environments, but for optimal performance it’s essential to select the right resin for each application. SABIC (Riyadh, Saudi Arabia) subsidiary Petrokemya’s petrochemical complex in Jubail, Saudi Arabia, produces a variety of feedstock chemicals such as ethylene, styrene, chlorine, crude industrial ethanol and more. For the production process, the complex required a combustion unit with several large components and pipes that must withstand hydrochloric acid without corroding.

Design and manufacture of the combustion unit quench tank, scrubber, exhaust tank and associated vessels and piping was tasked to a team that included corrosion-resistant equipment fabricator (Martorelles, Spain), contractor China Tianchen Engineering Corp. (TCC, Tianjin, China) and engineering firm John Zink Hamworthy Combustion (Tulsa, Okla., U.S.). These components were required to withstand contact with hydrochloric acid, meet several design challenges and be a cost-effective solution.

Glass fiber-reinforced composites were chosen as a material able to withstand the highly corrosive chemicals, while offering a more cost-effective solution than specialized metal alloys. All major components were constructed from fiber-reinforced plastic (FRP), with a few minor exceptions including lifting and hold-down lugs (stainless steel), spray nozzles (thermoplastic or metallic) and scrubber packing.

To provide the most economic solution while satisfying performance requirements, Ollearis turned to three AOC (Collierville, Tenn., U.S.) Atlac resins. “We selected the resin types using the AOC Chemical Resistance Guide as well as the expertise from AOC’s technical service team, considering the fluids handled and the design temperatures detailed by the client. It was necessary to make sure the resins proposed would perform well under [the required] conditions,” explains Adriano Ureña, technical manager at Ollearis.

The quench tank and scrubber during trial and fit testing prior to installation.

Ollearis selected Atlac 590 epoxy Novolac resin for the quench tank, which is the first phase of the gas cleaning process. The tank measures 11.8 meters tall with an inside diameter (ID) of 3 meters. The challenge is that when operational, exhaust gas from the combustion unit enters this quench tank at a temperature of approximately 300°C, and is then cooled very quickly by water sprayed from nozzles near the gas inlet. Atlac 590 was chosen to provide resistance to hydrochloric acid solution and retention of strength at the required elevated temperatures.

For the 14.10-meter-tall scrubber, the 39.7-meter-tall exhaust stack from which the cleaned gas is released and the 1.45-meter-long duct connecting the scrubber and the quench tank, Atlac 430 bisphenol A epoxy vinyl ester resin was chosen. This is said to be a versatile, standard product matching the comparatively less challenging temperature conditions for these components — the scrubber’s and exhaust stack’s design temperatures reach up to 85°C. The scrubber is exposed to hydrochloric acid solution entering from the quench tank as well as sodium hydroxide solution present in the scrubbing water that is used to neutralize the acid. The exhaust stack also is exposed to air containing a small amount of hydrochloric acid and wet chlorine.

For the piping system installed around the scrubber and quench tank, Atlac 383 unsaturated bisphenol A polyester was chosen for its chemical resistance against acid and caustic fluids at a lower cost than standard vinyl ester resins.

The quench tank, scrubber and cylindrical parts of the stack were manufactured via a hybrid manufacturing process, combining wet filament winding with an exterior layer of bidirectional woven fabrics applied simultaneously. This combination produced parts with better mechanical properties in both the hoop direction (from the filament winding) and axial direction (from the fabrics, which align with the part axis). The addition of woven fabric also reduced the weight percentage of glass fiber per part, from 70% for a fully filament-wound part to 55%. This increases the amount of corrosion-resistant resin per part. Other components were produced via hand layup.

Solving design challenges

Ollearis faced several challenges when designing the equipment for this project. One challenge came from the need to include a resin-heavy corrosion-barrier layer on the inner surface of the quench tank, which posed risks of crazing — or cracking — due to thermal shock during operation. The team improved the component’s resistance to thermal shock by reinforcing the corrosion barrier with a carbon fiber surfacing veil.

The final installed system at the Petrokemya facility.

A second challenge was that Ollearis needed to find a way to support the weight of packing inside the scrubber — the packing is the material that removes the gases from the air passing through the scrubber. To solve this, Ollearis installed a composite grating below the packing, supported by a composite ledge and two composite beams. The ledge and beams have a hollow, rectangular cross section, and the ledge is filled with polyurethane foam. The ledge was manufactured directly into the filament-wound cylindrical scrubber as one piece; bonding after manufacture would pose a risk of debonding due to loads from the packing weight. The beams are supported by specially designed composite nozzles bonded to the scrubber shell.

A third design challenge came from the fact that the quench tank and scrubber operate under vacuum but have flat bottoms — flat composite panels have poor resistance to pressure and vacuum and usually need to be very thick to withstand such loads, making them expensive to manufacture. To meet project targets, Ollearis developed a less costly solution by using a sandwich construction comprising a core of resin-impregnated 3D glass fiber fabric faced with composite skin layers, to reduce the cost and weight of a solid composite part.

For this project, the composite components were engineered and delivered in 2016, with final installation completed in 2017.

Related Content

Plant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreMFFD longitudinal seams welded, world's largest CFRTP fuselage successfully completed

Fraunhofer IFAM and partners have completed left and right welds connecting the upper and lower fuselage halves and sent the 8×4-meter full-scale section to ZAL for integration with a cabin crown module and testing.

Read MoreRead Next

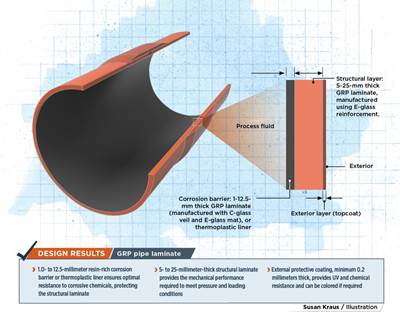

Corrosion-resistant composite piping over the long haul

Three decades of lessons learned using corrosion-resistant glass fiber-reinforced composites in piping at SABIC’s Netherlands chlorine production plant.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read More

.jpg;width=70;height=70;mode=crop)