Prepregs

Enduredge NTC-425 prepreg enables flexible composites fabrication

Low-cost, vertically integrated cyanate ester system from Nexx Technologies has an extended out-time and is capable of parts production in and out of the autoclave.

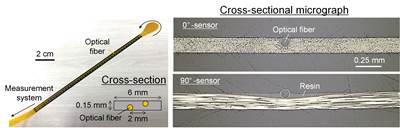

Read MoreMeasuring ply-wise deformation during consolidation using embedded sensors

Strip-type shape sensor method claims real-time measurement of ply-wise deformation.

Read MoreHaydale graphene-enhanced prepreg achieves notable tool life extension

Extended field trials substantiate functionalized prepreg material features, such as doubled composite parts manufacture, tighter-tolerance parts and more.

Read MoreMetal AM advances in composite tooling, Part 1

Multiple metal additive technologies are gaining market acceptance and interest for composite tooling used in processes ranging from short-fiber injection to autoclave-cure prepreg.

Read MoreDiab Divinycell HM foam lightweights Mayla 44 electric powerboat

Ultra-high-performance powerboat achieves high weight reduction with carbon fiber sandwich construction of the deck, internal structure and the complete hull surface.

Read MorePRF Composite Materials introduces RP570 FR eXpress cure prepreg system

Ultra-fast, fire-retardant formulation targets snap cure press molding of structural components.

Read MorePRF Composite Materials announced as material supplier for ThrustWSH

ThrustWSH aims to set a new water speed record with an innovative, composites-intensive hydroplane design, targeting a 2025/26 run date.

Read MoreCygnet Texkimp builds high-precision slitter spooler rewinder for industry trials

Demonstration machine can precisely slit and wind up to 48 tapes from continuous thermoset UD carbon fiber prepreg, with additional material compatibilities.

Read MoreHexcel HexPly M9.6 prepregs receive type approval for marine use

Third-party certification guarantees lightweight composite quality, performance and consistency for more sustainable marine vessels.

Read MoreCAMX 2022 exhibit preview: Current Inc.

Current Inc. produces thermoset-based products such as tubing rods, sheets and more with high electrical and mechanical characteristics and different color combinations.

Read More