Prepregs

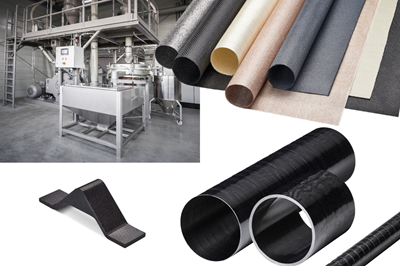

CAMX 2021 exhibit preview: Ensinger

Ensinger offers a wide portfolio of products and services for thermoplastic composites, including its Tecatec materials range and polymer pulverizing and development services.

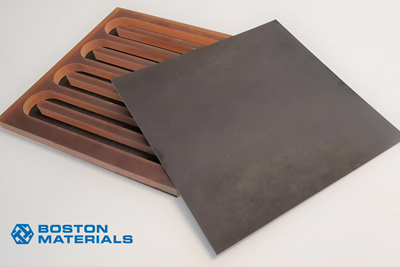

Read MoreCAMX 2021 exhibit preview: Boston Materials

Supercomp, ZRT and Bimetal are three of Boston Material’s z-axis carbon fiber products developed via its patented magnetic alignment process.

Read MoreKamm Projects launches carbon fiber aero-road bike

U.K.-based composites company combines passion with decades of industry experience to develop a next-gen bike that offers more stiffness, speed, comfort, efficiency, precision and response.

Read MoreMore Affordable Small Aircraft Manufacturing project in Clean Sky 2 replaces metal nacelle with composites

SAT-AM project composite nacelle reduced component weight by at least 10%, reduced the number of elements by more than 35%, resulted in a more uniform structure and reached TRL 6.

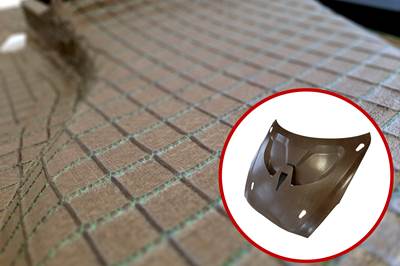

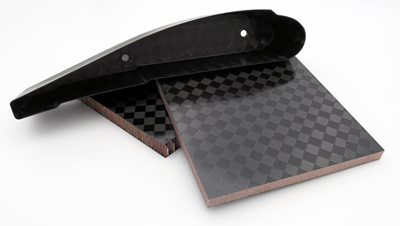

WatchComposites Evolution, Bcomp launch Evopreg ampliTex flax-epoxy prepregs

Compatible with Bcomp’s powerRibs reinforcement grid, the family of natural fiber materials drives enhanced stiffness, lightweight and a reduced footprint for motorsports and high-performance automotive applications.

Read MoreHexPly M901 prepreg accelerates product development cycles

Hexcel’s HexPly M901 prepreg system reportedly reduces production time of composite leaf springs.

Read MoreToray Composite Materials America launches flexible, adaptive 2700 prepreg system

Particularly geared toward emerging aerospace programs, the epoxy-based meets demands for high performance and process flexibility from prototype to high-volume production.

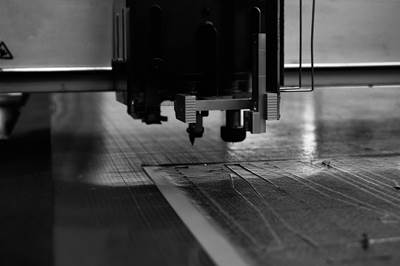

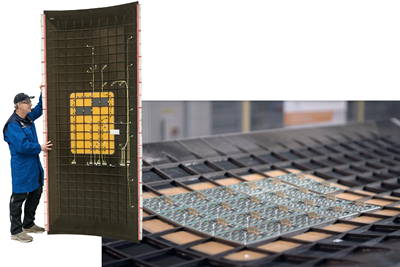

Read MoreIntegrating antennas into composite aerostructures

ACASIAS project integrates Ku-band array antenna in novel AFP orthogrid with drastically reduced tooling for more fuel-efficient, multifunctional CFRP aircraft fuselage panel.

WatchAxiom prepregs target pressure vessels

Axiom Materials has launched two new narrow prepreg products developed for use in pressure vessels to store compressed natural gas (CNG) and hydrogen for e-mobility applications.

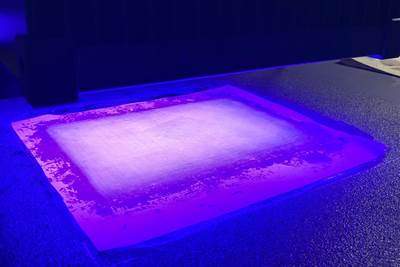

Read MoreEasy-to-use kits enable infield repair of composite structures

Portable kit enables patch repairs using UV-cure glass fiber/vinyl ester or room-temp stored carbon fiber/epoxy prepregs and battery-powered curing equipment.

Read More