Composites Evolution, Bcomp launch Evopreg ampliTex flax-epoxy prepregs

Compatible with Bcomp’s powerRibs reinforcement grid, the family of natural fiber materials drives enhanced stiffness, lightweight and a reduced footprint for motorsports and high-performance automotive applications.

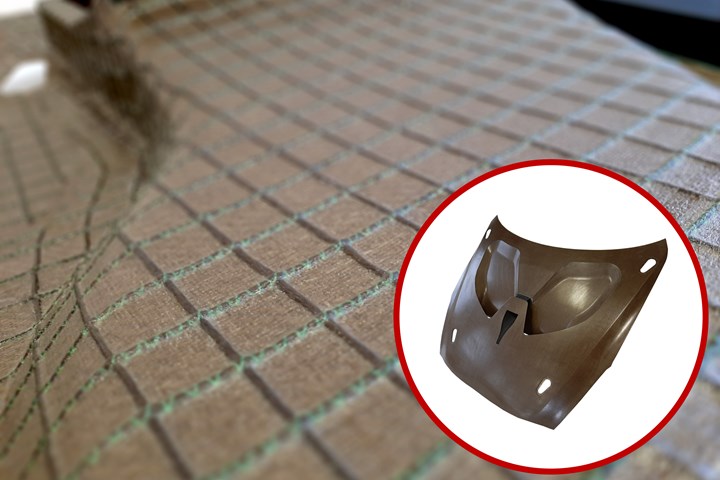

Retrac Group’s bonnet demonstrator with powerRibs. Photo Credit: Composites Evolution, Bcomp.

Composites Evolution Ltd. (Chesterfield, U.K.) has teamed up with natural fiber reinforcement specialists Bcomp (Fribourg, Switzerland) to launch a new range of flax-epoxy prepreg materials, designed to offer enhanced sustainability without compromising on performance. Evopreg ampliTex prepregs are said to combine Composites Evolution’s high-performance Evopreg epoxy resin systems with Bcomp’s award-winning ampliTex flax reinforcements, to deliver a family of materials that offer outstanding performance for component applications.

To reach the full performance of natural fibers, says the company, Evopreg ampliTex prepregs have been tailored to be compatible with Bcomp’s powerRibs reinforcement grid, enabling the same stiffness and weight as thin-walled monolithic carbon fiber parts while decreasing the CO2

footprint by 85%. Composites Evolution also notes that the family of materials improves safety, as it blunts braking behavior without the dangerous debris or sharp edges.

“Sustainability is an increasingly important factor for many of our customers — particularly those involved in motorsports and high-performance automotive applications,” says Composites Evolution’s Sales and Marketing Director, Ben Hargreaves. The company itself has more than 10 years of experience in the development and production of natural fiber prepregs “As you’d expect in these sectors though, sustainability can’t come at the expense of performance — the two must go hand-in-hand. This is something that other prepregs can struggle with, as natural fiber behave very differently to carbon or glass fiber, for example.”

He continues, “Working together with Bcomp, we can offer an unrivaled package of technical expertise and application know-how. We draw upon this to help customers understand the strengths and weaknesses of natural fiber composites, and to show where and how they can be adopted without the need for significant changes to existing composite component production processes.”

One such customer is U.K.-based Retrac Group, which houses a composites division that Composites Evolution claims is one of the U.K.’s most

experienced composites engineering companies across motorsports, automotive and aerospace. It recently used Evopreg ampliTex + powerRibs to produce a demonstrator bonnet panel for a race-bred supercar.

“We’re seeing a growing interest in flax fiber composites, particularly in the motorsports and niche vehicle sectors,” notes Retrac Group Project Manager Alan Purves. “It is therefore essential that we have developed an in-depth understanding of the processing requirements and performance capabilities of these materials, and are ready to respond to our customers' requirements. Being able to tap into the combined expertise and experience of both Composites Evolution and Bcomp is proving invaluable.”

Purves says Retrac’s laminators found the Evopreg ampliTex materials easy to use, with good drape and tack to the molds. “The finished part looks great, and we shall showcase it later in the year,” he says.

The bonnet demonstrator is a two-part molding, with both inner and outer produced using Evopreg ampliTex EPC300-F300T 2x2 twill prepreg, backed with powerRibs. The air duct components were 3D-printed at Retrac, using the company’s Stratasys (Eden Prairie, Minn., U.S.) Fortus 450MC machine.

Bonded using polyurethane adhesive to minimize A-surface witnessing, the whole assembly weighs only four kilograms.

Johann Wacht, motorsports manager at Bcomp Ltd concludes: “We share the view that sustainability and performance need to go hand in hand and are proud that already during the development phase of Evopreg ampliTex several OEMs and parts manufacturers have fully validated the prepregs.”

Related Content

Notox surfboards harness flax fiber for wave surfing competition

Libeco flax, Airbus rCF fabrics, Sicomin GreenPoxy bioresins and an agave core form a heavy, robust surfboard custom-designed for Clément Roseyro in this year’s Nazaré Big Waves Surf event.

Read MoreBio-based SiC ceramics from wood polymer composites

Austrian research institute Wood K plus makes 95% silicon carbide ceramics more sustainable (>85% bio/recycled content), enables 3D shapes via extrusion, injection molding and 3D printing.

Read MoreEvolving natural fiber technology to meet industry sustainability needs

From flax fiber composite boats to RV exterior panels to a circularity model with partnerships in various end markets, Greenboats strives toward its biomaterials and sustainable composites vision in an ever-changing market.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreRead Next

McLaren, Bcomp use natural composite fibers in F1 racing seat

The flax fibers meet strength and stiffness requirements while reducing vibration, cost, enhancing safety and lowering its CO2 footprint by 75%.

Read MoreAll-electric SUV motorsport vehicle incorporates Bcomp natural fiber bodywork

In preparation for the Extreme E racing series, Spark vehicles use ampliTex and powerRibs technologies for more sustainable, efficient and safe off-roading.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read More