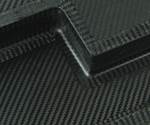

Composites Evolution introduces Evopreg EPC200 epoxy prepreg

Evopreg EPC200 enables variable temperature cure with good surface finish.

Source | Composites Evolution

Prepreg supplier Composites Evolution (Chesterfield, U.K.) has expanded its Evoprep EPC component epoxy range with the launch of its variable temperature curing prepreg, Evopreg EPC200. Based on a toughened epoxy resin system, the company says it enables curing between 65°C and 120°C when using vacuum bag/oven, out-of-autoclave (OAA) or press-molding processes.

The company notes that Evopreg EPC200 is primarily aimed at fabricators using low-temperature, OOA molding processes who want to produce components with a high-quality surface finish. Composites Evolution also says the epoxy prepreg has a flexible cure profile, which makes it ideal for rapid processing at high temperatures, reducing production time while simultaneously maintaining the same level of performance.

Composites Evolution Evopreg EPC component resins are available in a range of carbon, glass, aramid and ampliTex flax reinforcements.

Related Content

-

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

-

Co-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

-

Plant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.