PEEK

In oil and gas, an additive manufacturing standard (API 20T) will aid adoption of composites

Polymer AM equipment maker Roboze sees how the oil and gas industry’s way forward with additive is like that of another high-stakes industry, aerospace, and also different in important aspects.

WatchHitachi Rail chooses Roboze printers, materials including carbon fiber/PEEK for railway spare parts

The Roboze ARGO 500 will be used at Hitachi Rail factories in Naples, Italy and Maryland, U.S. to reduce cost and delivery times for prototypes and spare parts.

Read MoreFormula 1 team adopts Roboze 3D printed composites

The Visa Cash App RB Formula 1 team is collaborating with Roboze to reduce weight and create parts with complex geometries via carbon fiber/PEEK.

Read MoreClean Sky 2 OUTCOME project demonstrates PEEK thermoplastic composite wingbox cover

Airbus Defense and Space, FIDAMC and Aernnova demonstrate out-of-autoclave, one-shot process for wingbox cover with integrated stringers for regional aircraft.

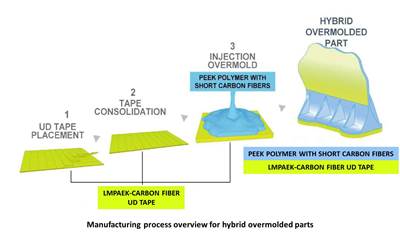

Read MoreTool Gauge, Victrex partner to develop co-molded composite aircraft parts

Novel hybrid overmolding technology achieves novel thermoplastic composite parts to replace machined aluminum components on commercial aircraft, as well as reduce manufacturing costs and timeline.

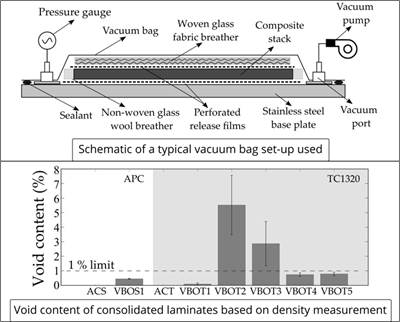

Read MoreTPRC research studies void removal mechanisms in VBO processing

New publication evaluates vacuum bag only-consolidated carbon fiber/PEEK tapes to determine the role of different void removal mechanisms in thermoplastic composites.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreTri-Mack introduces thin, lightweight thermoplastic composite enclosures

Durable, low-cost manufacturing support wide range of industrial uses, with option for embedded EMI shielding.

Read MoreMaterials & Processes: Tooling for composites

Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. The material type, shape and complexity depend upon the part and length of production run. Here's a short summary of the issues involved in electing and making tools.

Read MoreMaterials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read More