TPRC research studies void removal mechanisms in VBO processing

New publication evaluates vacuum bag only-consolidated carbon fiber/PEEK tapes to determine the role of different void removal mechanisms in thermoplastic composites.

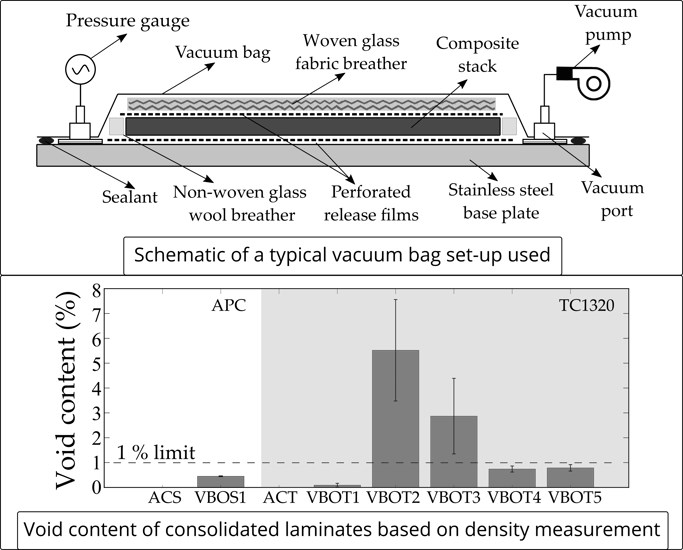

Schematic of a typical vacuum bag setup used (top) and void content of consolidated laminated based on density measurement (bottom). Photo Credit: Jagadeesh Swamy, Wouter Grouve and Remko Akkerman/TPRC

ThermoPlastic composites Research Center (TPRC, Enschede, Netherlands) PhD student Jagadeesh Swamy has recently published an experimental study on the role of different void removal mechanisms in vacuum bag-only (VBO) processing of advanced thermoplastic composites. The research was performed at TPRC in close cooperation with researcher Remko Akkerman’s Production Technology research group from (UT, Enschede)

The current study is focused on understanding the role of different void removal mechanisms in VBO processing of advanced thermoplastic composites. For this purpose, two commercially available carbon fiber-reinforced polyetherketoneketone (CF/PEKK) tape materials were evaluated, distinct in morphologies, such as surface roughness and fiber-matrix distribution, and physical characteristics.

The VBO consolidation results proved that the void reduction and removal mechanisms varied depending on the tape material; for example, a difference in the consolidation dwell time was observed to achieve <1% void content parts, which indicates that despite the tapes having the same polymer type matrix, they differ in their diffusion behavior.

Two causes for the difference in the times required for consolidation have been pinpointed. First, the diffusion coefficients may be different for the two tapes. Although the matrix material in both tapes is PEKK, the exact formulation is unknown. Second, the volume of gases, which comprises entrapped air and the volatiles that evaporate during the process, may be different.

Read the full article, “An experimental study on the role of different void removal mechanisms in VBO processing of advanced thermoplastic composites” .

Read about other project developments made in cooperation with TPRC:

- New developments released for ply-ply friction prediction

- TPRC research project investigates thermoplastic composite structure repair strategies

Related Content

-

Revisiting the OceanGate Titan disaster

A year has passed since the tragic loss of the Titan submersible that claimed the lives of five people. What lessons have been learned from the disaster?

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

Development of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.