Molds/Tools

Decision SA, Carboman Group unveil new direct mold tooling for aerospace applications

Material selection ensures tool surface and support structure match mold and part CTE for short lead times and highly stable direct molds at temperatures up to 180ËšC.

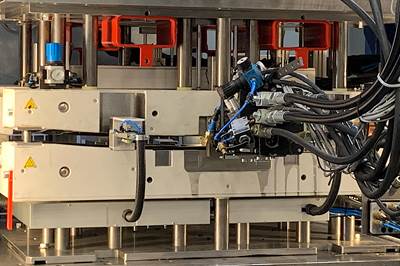

Read MoreInnovative tooling, automation enable new line of composite window wells

Moldmaker and automation specialist Commercial Tool Group provided RockWell with custom compression molds and robotics to enable high-volume, low-cost production.

Read MoreInvar, wire additive manufacturing expand aerocomposite tooling options

Invar facesheets and backing structures are candidates for large-format 3D printing to more quickly and efficiently produce aerostructures tooling.

WatchUMaine awarded $2.8 million to accelerate AM wind blade development

Additive manufacturing with bio-based, 100% recyclable feedstocks reinforced with wood can reduce construction time by six months and cut costs by 25-50%

Read MoreComposites mold manufacturer, BBG, is finalist for Germany’s best toolmaker 2020

Smart molds for Industry 4.0 applications key to its recognition in “Excellence in Production” competition.

Read MoreUniversity of Stuttgart, Institute of Aircraft Design uses adaptive mold technology from Adapa

Reconfigurable mold aids development of digitally-manufactured composite parts for reduced-emissions transport vehicles.

WatchTrelleborg launches high-temperature tooling material for direct-to-part manufacture

The tooling material has operating temperature of up to +180ºC, low CTE, offers an alternative to aluminum, prepreg and steel for high-volume part production.

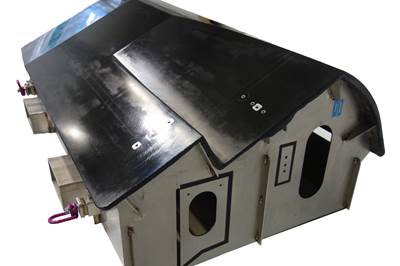

Read MoreBraided preforms meet phase-change tooling

A program from the U.S. Air Force Research Laboratory adopts automated braiding and phase-change tooling for a complex geometry unmanned aircraft part.

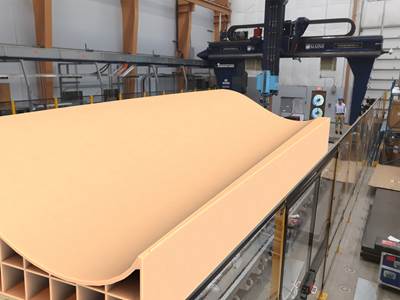

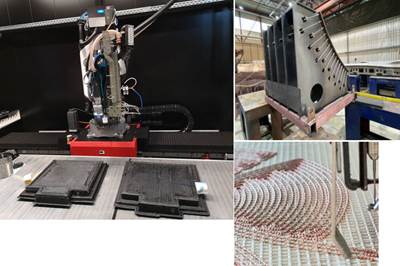

WatchThermwood demonstrates novel 3D printing approach for large vessel molds

Thermwood 3D-printed and trimmed five-foot-tall sections that were then bound together and bolted to form a complete female mold. The entire mold section, made of four printed pieces, weighs 4,012 pounds and required 65.5 hours to print.

Read More3D printing CFRP molds for RTM flaperon, exoskeletons and more

The Chair of Carbon Composites at TU Munich is advancing composite additive manufacturing via large-scale extrusion, continuous fiber printing, integrating heating into tools and more.

Read More