Filament Winding

Making continuous composite pipe

The continuous filament winding process was developed in the 1970s by Danish inventor Frede Hilmar Drostholm, and it was commercialized first by Toledo, Ohio-based Owens Corning’s engineered pipe systems business, in partnership with several entities, including Amiantit (Dammam, Saudi Arabia) and Vera Fabrikker (later Flowtite Pipe and Tank AS, Sandefjord, Norway). The ingenious process involves a cantilevered, horizontal rotating mandrel system.

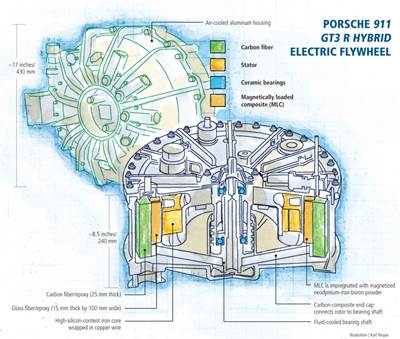

Read MoreComposite flywheel: HEV racing dynamo

Electric flywheel energy storage system powers Porsche 911 hybrid electric vehicle (HEV) to endurance racing victory.

Read MoreTough resins for aggressive environments

New thermoset systems drive composites deeper into markets where fire, corrosion, stress and fatigue are ever-present threats.

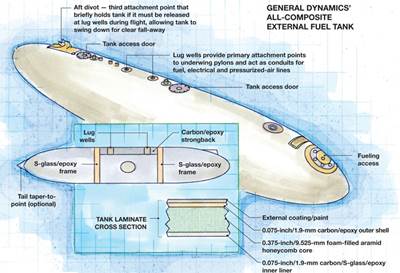

Read MoreCarrier-capable, all-composite external fuel tank

Legacy product positions builder for a shot at an F-35 contract.

Read MoreMae West: Pipe dream in Munich

Unique fiber architecture and mandrel-less filament winding process make “impossible” rotational paraboloid sculpture possible in carbon composites.

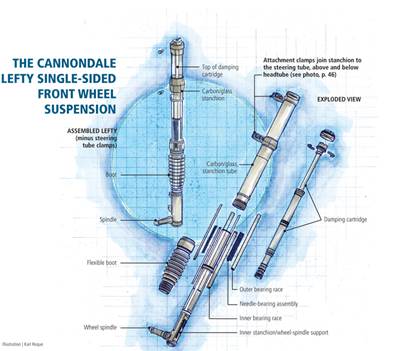

Read MoreIn search of a better ride

Composites minimize weight on this mountain bike’s unconventional, single-sided front-wheel suspension system.

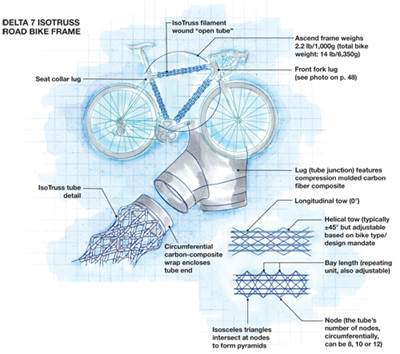

Read MoreNew twist in cycling: A truss bikers can trust

An "open tube" alternative to the solid-tube bike frame.

Read More