Filament Winding

Automated filament winding aids segmented blade production

Roth Composite Machinery system is part of ENERCON’s optimized production for modular blades.

Read MoreHuntsman researching opportunities for graphene-enhanced nanocomposites

The company is working on incorporating graphene into its Araldite epoxy resins.

Read MoreMikrosam delivers automated filament winding line to Magna

Integrated production cell for high-volume production of composite CNG tanks installed in Graz, Austria plant.

Read MoreContinuous filament winding: A short history

The process continues to make composite pipe production increasingly competitive with steel and concrete

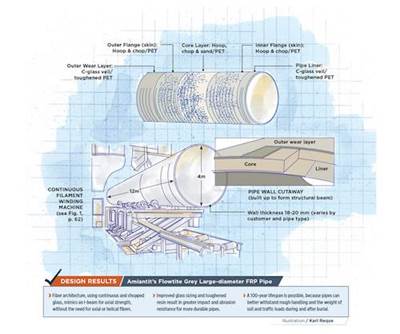

Read MoreEngineering large-diameter underground pipe

A combination of design and new materials enhances pipe performance without adding cost.

Read MoreComposite tanks best stainless steel over road, rail and sea

One-piece, filament wound containers cost less, hold more, last longer.

Read MoreConverting the structural chassis to composites

Germany’s largest producer of GRP leaf springs for cars and trucks broadens its product range to CFRP stabilizer bars, which cut weight 50% vs. steel.

Read MoreFine-tuning fiberglass: Smart fiber sizing

Some insights into those proprietary chemistries that can customize performance at the fiber/resin interface.

Read MoreComposites manufacturing — where the excitement lives

A regular CW columnist and the chief commercialization officer for the Institute for Advanced Composites Manufacturing Innovation (IACMI, Knoxville, TN, US), Dale Brosius points out that for today's engineering students, a Ph.D in manufacturing could open the door to an exciting, alternative career path.

Read MoreAutomation: Robots taking off in commercial aircraft

Will this affordable and versatile class of multiaxis manufacturing hardware and software drivers enable airframers to reduce costs and speed deliveries?

Read More