Fabrics/Preforms

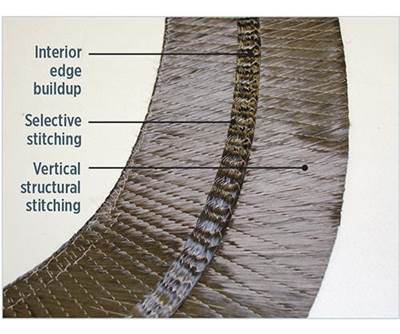

Selective reinforcements boost “commodity” composite properties

Strategically placed advanced reinforcements reduce weight, cost while dramatically increasing mechanical performance and dimensional stability.

Read MoreJEC World 2016, the full report

ÂÌñÏ×ÆÞ's editors report on the technologies and products that caught our eye at JEC World 2016, in early March.

Read MoreMaterials & Processes: Composites for repair

Composites offer cost-effective means to repair, protect and/or strengthen structures made of steel, concrete or other materials.

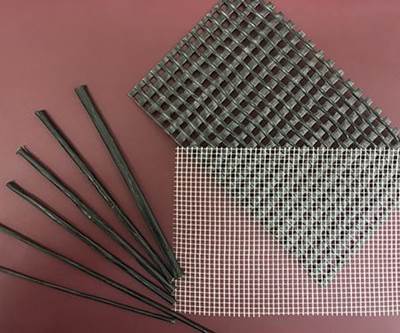

Read MoreMaterials & Processes: Fiber formats for composites

Fibers used to reinforce composites are supplied directly by fiber manufacturers and indirectly by converters in a number of different forms, which vary depending on the application. Here's a guide to what's available.

Read MoreToho Tenax develops production system for carbon fiber composites

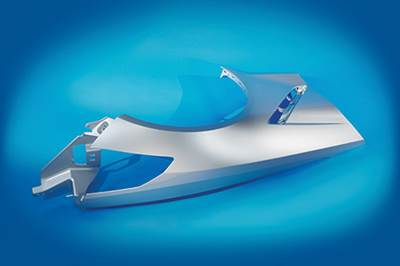

The process combines Toho Tenax' Part via Preform technology with high-pressure resin transfer molding (HP-RTM) to speed manufacture of carbon fiber composites.

Read MoreLower cost, less waste: Inline prepreg production

New technologies move direct (fabricator-based) prepregging closer to reality.

Read MoreFirst 3D woven composite for NASA thermal protection systems

A NASA-led team develops 3D woven quartz preform, hybrid process to infuse it with cyanate ester resin (0.5% voids) and achieves TRL5 in three years to replace CF/phenolic in the Orion spacecraft’s compression pads.

WatchJEC World 2016 exhibition and product previews

JEC World 2016 will be held in Paris March 8-10. These are some of the products that will be found at the show.

Read MoreResin transfer molding: An update

Fulfilling the promise of OOA composites without sacrificing pressure.

Read MoreOOA overview: Market & opportunities

CW looks at where aero-OEMs and their suppliers are finding out-of-autoclave alternatives.

Read More