Ceramic Matrix Composites

3M launches high-temperature, oxidation-stable Nextel ceramic fabric

Nextel 610 DF-13-4500 ceramic fabric allows ceramic composites to compete with metal components, with comparable performance and reduced cost.

Read MoreAxiom Materials opens High-temperature Composite Center

The 3,500-square-meter facility expands the U.S.-based company’s CMC production capabilities to support increasing demand in aerospace and industrial applications.

Read MorePratt & Whitney to open ceramic matrix composites facility

The 60,000-square-foot R&D facility in Carlsbad, Calif., U.S. will focus on the design, development and production of CMCs for aerospace applications.

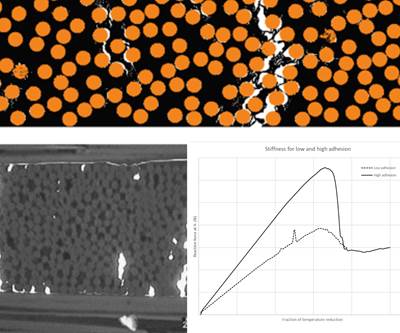

Read MoreA new definition of composites?

Nucleation and control of crystallinity plus aspect ratio creates new plastic and ceramic composites with tailored performance.

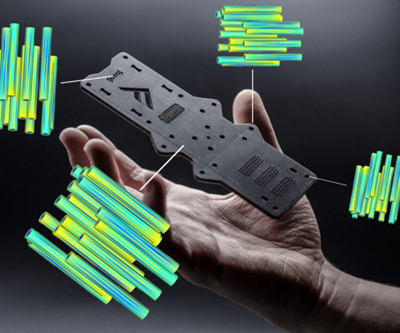

Read MoreMagnetic 3D printing the next generation of tailored composites

Fortify uses magnetic fields and digital light processing to produce tailored microstructures for high-resolution, 3D printed composite parts — and enables the next generation of multiscale, multifunctional composite metamaterials.

WatchNanomaterials: Products, supply chain mature for next-gen composites

Development spans 3D and thermoplastic nanocomposites, nano-CMCs for hypersonics and nanomaterials safety and toxicity.

Read MoreDLR selects MultiMech for crack prediction in CMC components

The German Aerospace Center has selected MultiMechanics’ modeling and simulation software to perform advanced crack prediction during the manufacturing of ceramic matrix composite components.

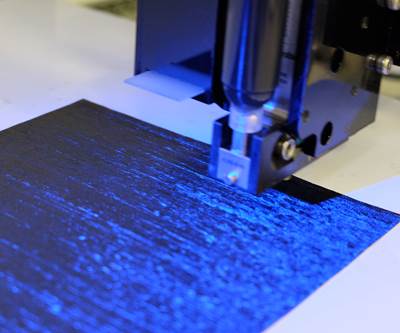

Read MoreFusing waterjet, laser for efficiency in CFRP/CMC machining

Laser MicroJet technology offers high accuracy and speed without heat issues, burring or replacement of cutting tools.

Read MoreL&L Special Furnace Co. unveils retort furnace for de-bindering ceramic composites

The company is customizing a large retort box furnace for de-bindering ceramic matrix composite (CMC) prepreg materials.

Read MoreCAMX 2018 preview: IKONICS

IKONICS Advanced Materials Solutions (Deluth, MN, US) is showcasing its Precision Abrasive Machining (PAM), a non-traditional machining process.

Read More