Ceramic Matrix Composites

Lockheed Martin expands development, production of ultra-high temp CMCs with facility expansion

Targeting current and future needs in hypersonic and aeronautics applications, Lockheed Martin Skunk Works’ Allcomp team is increasing and digitizing its capabilities in ceramic matrix composite (CMC) materials and parts fabrication.

Read MoreAxiom partners with NIAR ATLAS for oxide-oxide CMC research

Partnership breaks cost and process scalability barriers through the development of oxide-oxide CMC prepreg using AFP technology.

Read MoreRATH prepares for production of advanced oxide ceramic fiber for CMC

New facility in Germany is part of regional supply chain and vision to lead green energy transition using CMC, supported by German government and Composites United’s Ceramic Composites network.

Read MoreMulti-composite thrust chamber aims to boost rockets, reduce cost for New Space economy

Black Engine uses new, microporous CMC liner for transpiration cooling and multiple lightweight composites in modular design that offers increased lifetime and lower maintenance versus current launch vehicle engines.

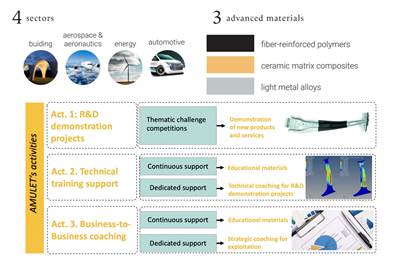

WatchAMULET project aims to create new value chains for fiber-reinforced polymers and CMCs

R&D demonstration projects targeting current challenges in auto, aero, energy and building will be developed to reach TRL7 with the goal of accelerating industrial use of advanced lightweight materials.

Read MoreMag7 Technologies offers advance licensing for graphene CMC technology

The company’s process produces graphene-enhanced ceramic precursor for use in ceramic matrix composite (CMC) applications.

Read MoreGE Aviation reaches advanced manufacturing milestone for CMC and AM jet engine components

This past July, two sites, Asheville, N.C., and Auburn, Ala., shipped their 100,000th CMC turbine shroud and 100,000th additively manufactured fuel nozzle tip respectively.

Read MoreCAMX 2021 exhibit preview: Revolution Composites

Revolution Composites’ triaxial braiding process uses a wide range of fibers for for thrusters, nozzles and conical shapes in spaceflight.

Read MoreResearchers work to prove out ultra-high-temperature CMC for NASA Interstellar Probe study

A recent study by Johns Hopkins and Advanced Ceramic Fibers LLC worked toward ceramic matrix composites able to withstand up to 3,500°C for space heatshields.

Read MoreCFM RISE program targets composites, additive manufacturing and hybrid electric

GE Aviation, Safran program targets more than 20% lower emissions, 100% compatibility with sustainable and hydrogen fuels, with a technology roadmap detailing CMC, composite fan blades and more.

Read More