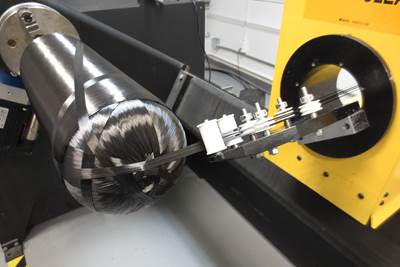

Braiding

Hawthorn Composites awarded structural inlet duct manufacturing contract

Manufacture of inlet ducts for Kratos unmanned combat aerial vehicle involves an automated dry fiber overbraiding process, VARTM infusion and oven cure.

Read MoreCarbon fiber windsurf fin incorporates Sicomin bio-based epoxy resin

Sicomin GreenPoxy 33 meets high-performance windsurfing fins requirements, accommodating significant loads, high torsion stiffness and flexibility.

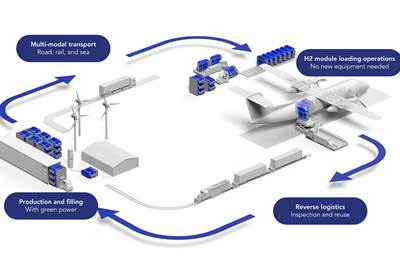

Read MoreUniversal Hydrogen uses dry braided carbon preform tanks as part of plan to decarbonize aviation

Twin-tank module offers low capex option for regional carriers to convert to clean fuel.

Read MoreBBG presents self-closing HP-RTM molds for CFRP compact hydrogen tank production

The autonomous concept, sufficient for series production, enables lower investment costs. Up to 15 cylinders can be produced simultaneously per operation.

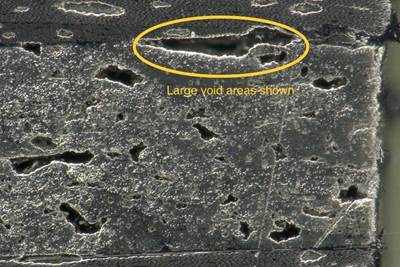

Read MorePart 2: Performance and safety benefits of prepregs

Returning with his second installment, Brian Bishop discusses the performance and safety benefits to using prepreg, and the value they can bring to composites fabricators.

Read MoreA&P Technology offers virtual tour for National Composites Week

Hosted by the Midwest chapter of SAMPE, the virtual tour will take place Aug. 27 from 4:00 to 5:30 p.m. ET.

Read MoreTeijin Ltd. Tenax carbon fiber qualified for Airbus A320neo

Tenax dry reinforcements non-crimp fabrics and braided fibers will form the skins and stiffeners via automated RTM.

Read MoreRediscovering the benefits of prepregs in composites manufacturing

Compared to more traditional forms of composites manufacturing, prepregs enable reduced manufacturing costs and enhance production performance.

Read MoreInnovative pressurized hydrogen storage for integrated vehicle structures using composites

Chained tubular storage tanks using semi-finished thermoplastic composite products offer flat designs aimed at easy integration into universal vehicle architectures.

Watch