Innovative pressurized hydrogen storage for integrated vehicle structures using composites

Chained tubular storage tanks using semi-finished thermoplastic composite products offer flat designs aimed at easy integration into universal vehicle architectures.

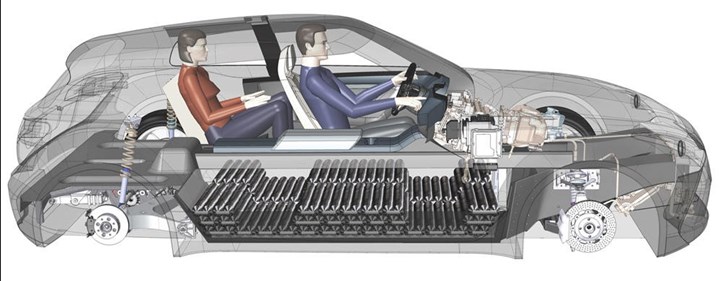

The multi-cell storage system enables efficient use of the limited space in modern vehicle designs. Source | © TU Dresden, ILK

The (Oslo, Norway) has proclaimed 2020 as the beginning of the "Decade of Hydrogen". To make significant progress toward emission-free road traffic, the Institute of Lightweight Engineering and Polymer Technology (ILK) at TU Dresden (Dresden, Germany) is participating in the 3.5-year BRYSON project (BauRaumeffiziente HYdrogenSpeicher Optimierter Nutzbarkeit). Translated in English as “space-efficient hydrogen storage with optimized usability,” the program is funded by the German Federal Ministry of Economics and Energy and is being pursued by a German consortium comprising BMW AG (Munich), ILK, composite engineering and development firm Leichtbauzentrum Sachsen (LZS, Dresden), composites distributor WELA Handelsgesellschaft (Geesthacht) and Munich University of Applied Sciences.

The aim of BRYSON is to develop new types of hydrogen pressure storage systems. These should be designed in such a way that they can be easily integrated into universal vehicle architectures. Therefore, the project focuses on the development of a flat design for tank container systems.

Integration concept to accommodate the pressurized hydrogen storage tanks in the floor of the InEco which was developed at ILK. Source | © TU Dresden, ILK

ILK is developing chained tubular storage tanks in close cooperation with LZS and herone GmbH (Dresden). (See “Injection-forming for high-performance, unitized thermoplastic structures”.) These tanks are manufactured from semi-finished thermoplastic fiber-reinforced composites based on braided reinforcements. Due to the high productivity of braiding and thermoplastics, this technology is intended to reduce the production costs of hydrogen tanks for fuel cell vehicles and enable easier recycling of the tank structures. This supports both improved competitiveness compared to battery electric vehicles and increased sustainability for the BRYSON approach. For more information, contact ³¾²¹¾±°ì.²µ³Ü»å±ð°ªâ€‹t³Ü-»å°ù±ð²õ»å±ð²Ô.»å±ð

Thermoplastic composites and integration as solutions

“The aim of the BRYSON program is to develop modular storage systems that can be adapted to any geometric design of the given vehicle design space,” says Alexander Rohkamm, co-founder of herone GmbH and the company’s project leader for Bryson. “The material processing properties of thermoplastic composites enable more integrated part designs as well as more cost- and energy-efficient manufacturing. This improves the ratio between performance and cost compared to conventional metal and thermoset composite solutions.”

“Alternative transportation concepts also need a rethinking in every step of the development and manufacturing chain,” notes Rohkamm. “In today's combustion engine vehicle architectures, gasoline and diesel drives share the same installation space, using the same architectures to achieve significant cost savings. Similarly, to achieve the greatest possible flexibility and economy in future electric vehicle architectures, hydrogen can be stored in the same installation spaces where high-voltage batteries would otherwise be located. Integrating both types of energy supply (hydrogen and battery) in the same installation space could enable scaling effects, reduced cost and more flexible production that can compensate for fluctuations in demand for either system.”

BMW’s commitment to hydrogen

According to Arian Dorofte’s March 30, 2020 article “,” BMW and fellow Hydrogen Council founding member Toyota Motor Corporation (Toyota, Japan), will continue their cooperation started in 2013 and aimed at industrialization of hydrogen fuel cell technology and production of scalable parts and modular components for hydrogen fuel cell vehicles. These components and the resulting powertrain will be deployed in the BMW i Hydrogen NEXT vehicle, schedule for 2022. BMW’s involvement in the BRYSON research project supports its aim to develop a safe and space-optimizing hydrogen storage system for fuel cell vehicles.

Related Content

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreOtto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreRead Next

Injection-forming for high-performance, unitized thermoplastic structures

Combining braided tape, overmolding and form-locking, herone produces one-piece, high-torque gear-driveshaft as demonstrator for broad range of applications.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read More