Biomaterials

FLOKI 6.5 mini racing yacht integrates bio-based Sicomin GreenPoxy resins

Staying true to the roots of its racing class, FLOKI 6.5 is built entirely from bio-based/recyclable raw materials without compromising on performance or processability.

Read MoreNCC proposes natural fiber use for SME subterranean transport network

Under an NCC SME Boost program, research indicates composite reinforcements will reduce material, manufacturing costs and prove more sustainable for innovative SME project.

Read MoreSicomin GreenPoxy resins contribute to first NFC wind turbine nacelle

Sicomin’s bio-based resins, intumescent FR gelcoats and UV-resistant clear coatings meet stringent requirements for Greenboats’ 7.3-meter natural fiber composite nacelle.

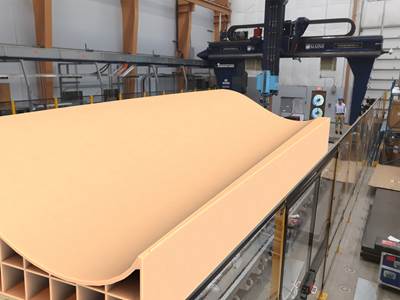

Read MoreUMaine awarded $2.8 million to accelerate AM wind blade development

Additive manufacturing with bio-based, 100% recyclable feedstocks reinforced with wood can reduce construction time by six months and cut costs by 25-50%

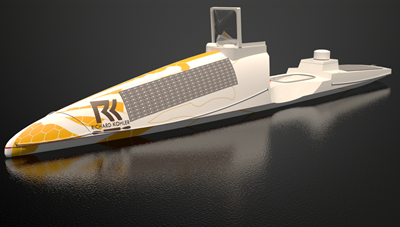

Read MoreSicomin-sponsored solo kayak crossing takes advantage of composites

Incorporation of Sicomin carbon fiber and PVC foam sandwich construction ensures an efficient kayak for extreme paddler Richard Kohler’s 6,700-kilometer journey across the South Atlantic.

Read MoreLingrove launches Ekoa Surface Peel N’Stick and receives automotive orders

Natural fiber/bio-thermoplastic composite veneers meet sustainability and performance demands for multiple markets.

Read MoreTeijin Aramid program produces bio-based, high-performance aramid fibers

The 2018 pilot program, in partnership with BioBTW, successfully produces Twaron yarn from bio-based aromatic materials without altering the material properties.

Read MoreAZL Aachen investigates potential for bio-based composite materials

The five-month market and technology study will start on October 22, 2020 and is open to interested companies.

Read MoreAimplas project develops biocomposite recycling methods

The ELIOT project, with the participation of the Dutch research center TNO, is developing recycling methods to improve sustainability in the aerospace industry.

Read MoreMcLaren, Bcomp use natural composite fibers in F1 racing seat

The flax fibers meet strength and stiffness requirements while reducing vibration, cost, enhancing safety and lowering its CO2 footprint by 75%.

Read More