Sicomin-sponsored solo kayak crossing takes advantage of composites

Incorporation of Sicomin carbon fiber and PVC foam sandwich construction ensures an efficient kayak for extreme paddler Richard Kohler’s 6,700-kilometer journey across the South Atlantic.

All photo credit: Sicomin

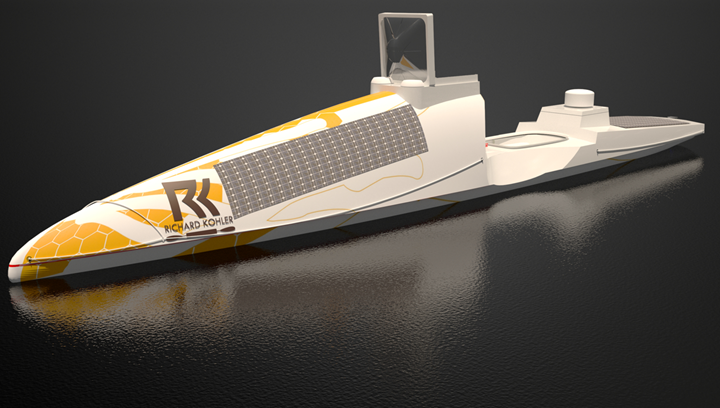

Sicomin (Châteauneuf les Martigues, France) a formulator and supplier of epoxy resin systems and high-performance composite solutions, announced on Jan. 25 its sponsorship of extreme paddler Richard Kohler’s solo kayak crossing of the South Atlantic. Working with its South African distributor, (Cape Town), Sicomin has provided GreenPoxy bio-based resins, adhesives and epoxy fairing compounds for the build of the eight-meter Ocean X craft that Kohler will paddle.

Formerly a Team Shosholoza America’s Cup sailor, Kohler switched to ocean kayak and surfski paddling a few years back. Now, as of Feb. 2021, he will leave Cape Town, South Africa, and attempt to paddle, solo and unsupported, 6,700 kilometers to Salvador in Brazil, crossing the South Atlantic in his custom designed, torpedo- shaped kayak.

Andrew Parsons from Aerontec, who first became involved in the project in 2020, was able to support Kohler, working alongside designers Richard Bertie and Phil Southwell and Ocean X’s builder, Dylan Soares de Melo — local composite specialists from Further Composites — with a package of Sicomin materials.

Extreme paddler, Richard Kohler.

Because Kohler will be paddling alone and unsupported, Parsons says, his kayak needs to provide shelter and be capable of carrying all of his provisions for a 2-3 month trip, while also being light enough for a solo paddler to keep moving through ocean swells. To achieve these requirements, Sicomin’s GreenPoxy 33 laminating system was used for a full, lightweight carbon fiber and PVC foam sandwich construction, with SR7200 epoxy adhesive used for all structural bonding of the kayak’s components.

“For the South Atlantic crossing, Ocean X needs to be strong, light and efficient. Working with Sicomin and Aerontec has been great,” says Kohler. “We’ve got fantastic materials for the build that are more sustainable than traditional epoxies and we’ve had brilliant technical support from the Aerontec team too. I can’t wait to get started now and show everyone what this new design can do.”

In addition to the personal challenge, Kohler is also using his trip to raise funds for the charity Operation Smile, which is active in 34 countries.

Kohler is currently carrying out final preparations to Ocean X and is planning to set off at the end of February, or as soon as the COVID-19 situation in South Africa allows. His journey can be followed on his Instagram channel: richardkohleradventures and on the Sicomin channel: greenpoxy.

Related Content

-

MiniLab consortium produces first full-scale thermoplastic composite hydrofoils

Project advances toward first recyclable foils for ocean racing, part of “Infinite Foil” finalist for JEC Innovation Award 2025.

-

CEAD launches the Maritime Application Center dedicated to industrial 3D printing boat hulls

The MAC is an LFAM-powered production facility equipped with highly automated, digitally driven manufacturing processes and built around a collaborative model to develop the boats of the future.

-

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.