Automation

EmbraerX unveils new flying vehicle concept for future urban air mobility

The eVTOL design focuses on user accessibility, low noise and the ability for autonomous flight.

Read MoreCarbonPro box: new forming process

From materials to assembly, the carbon fiber composite CarbonPro box manufacturing process features innovative, automated preforming technologies.

Read MoreCollaborative robotics system built for larger fiber loads

Cygnet Texkimp’s collaborative robot system is designed to lift packages of fiber weighing up to 35 kilograms.

Read MoreAutomated, in-situ inspection a necessity for next-gen aerospace

Inline inspection technologies continue to evolve with the aim of providing faster and more accurate part inspection.

Read MoreHenkel opens European hub for aerospace adhesive solutions

The new production plant in Spain supports lightweighting, fuel efficiency and automation for aerospace applications.

Read MoreTackling the aerospace supplier’s dilemma: Scalability

Automation and robotics can go a long way toward increasing capacity and growing a business dedicated to aerospace manufacturing. But Trinity Precision has learned that refining the indirect and unseen aspects of its operations can be just as valuable.

Read MoreWeb Industries releases brochures highlighting aerospace composites solutions

The downloadable brochures highlight Web’s automation development center and its suite of aerospace solutions.

Read MoreBasalt fiber composite design wins NASA 3D Printed Habitat Challenge

New York-based AI SpaceFactory’s MARSHA prototype uses automation and composites to create a stronger, more durable space habitat.

Read MoreNew Products: April 2019

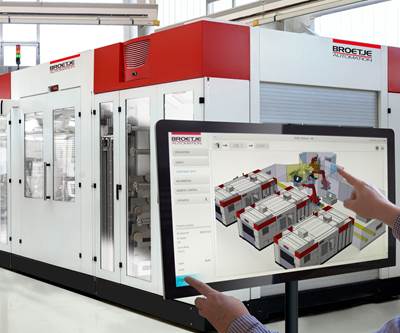

CW’s roundup of new products for the composites industry – the past month has seen innovations from Ahlstrom-Munksjö, Airtech, Broetje-Automation, Chromaflo Technologies, Holland Composites BV, Michelman, Nouryon, Petro Lube, PostProcess Technologies, Sicomin, Toray and Xenia.

Read MoreBroetje-Automation enlarges AFP portfolio for serial composite production

The STAXX product line of automated fiber placement (AFP) machining centers is designed for both thermoplastic and thermoset composite applications.

Read More