Autoclave

Combination of automation, rigid foam core enable high-volume aircraft part production

A feasibility study demonstrates increased production capacity using Evonik foam core and automated manufacturing.

Read MoreHexcel carbon fiber prepreg selected for ultralight aircraft design

German aircraft specialist Flight Design is using HexPly M79 for composite parts on its F2 aircraft.

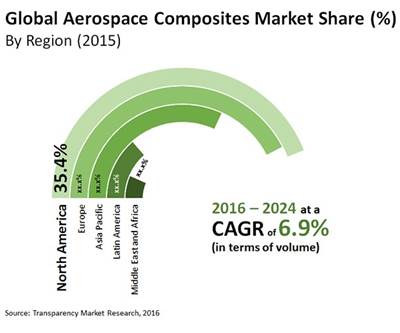

Read MoreTransparency Market Research releases Aerospace Composites Market report

Findings predict the global aerospace composites market value and trends between 2016 and 2024.

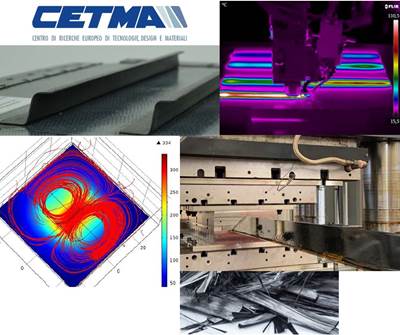

Read MoreCETMA: composites R&D and innovation in Italy

From design and simulation to inline inspection, induction welding, continuous compression molding and recycled carbon fiber, this lab to support industry is advancing composites in aerospace, automotive, construction and more.

Read MoreRockwood Composites, Leonardo produce 10,000th blade for Eurofighter Typhoon

The delivery of the 10,000th blade for the towed decoy on Leonardo’s defense aircraft marks 10 years of partnership for the companies.

Read MoreAFRL evaluates braiding, SMP tooling and VARTM for lower-cost future engine inlet ducts

U.S. Air Force and Ohio-based composites team develop new process for S-shaped aerostructure.

Read MoreMS-21 completes fourth flight test for EASA certification

Single-aisle jetliner with out of autoclave composite wing steps closer to certification.

Read MoreComposites in the race to space

Advanced materials use in current and upcoming NASA missions.

Read MoreDemonstrator shows potential for graphene-enhanced composite tooling

U.K.-based collaborative project demonstrates lower-cost, graphene-enhanced composite tooling for aerospace use.

Read MoreEvonik rigid foam cores utilized for automated composites fabrication

Foam cores specialist Evonik is featuring the results of a joint study by Evonik Industries, Composite Technology Center GmbH and Deutsche Zentrum für Luft- und Raumfahrt e.V., on the use of rigid foam material in automated production.

Read More