Dornier 728 nose landing gear door. Source | Evonik

The aircraft industry uses carbon fiber/epoxy prepreg and honeycomb core for a variety of complex structural parts, such as wing access panels; wing flap track and fuselage belly fairings; leading and trailing edge parts; and spoilers, ailerons, winglets and landing gear doors.

However, according to Evonik Resource Efficiency GmbH (Essen, Germany), production of these parts cannot keep pace with market demand from aircraft OEMs seek to ramp up production rates. The problem is two-fold: time-intensive hand layup processes, and production bottlenecks inherent to the use of traditional honeycomb core for sandwich composites.

The open-cell structure of honeycomb core necessitates the use of potting materials to seal core edges, and requires the application of an adhesive film to bond the core material to the laminate skins. A time-consuming two-step curing process is also required to mold a honeycomb cored laminate.

As a solution, Evonik has been working with technology partners to study the feasibility of high-rate production of structural aircraft sandwich components using automated fiber placement (AFP) and automated tape laying (ATL) processes, and Evonik’s ROHACELL HERO polymethacrylimide (PMI) structural foam as an alternative to honeycomb core.

ROHACELL HERO is a rigid, closed-cell, structural foam core material first introduced in 2013, and certain grades are now Airbus AIMS (Airbus Industries Material Specification) 04-11-011 qualified flight approved as a core material. ROHACELL HERO’s high compressive strength, Evonik says, enables the material to cope with compaction during handling by vacuum robot arms; the closed-cell foam material also eliminates the additional molding and potting steps that cause process bottlenecks with honeycomb.

In a feasibility study completed in 2019, Evonik worked with Deutsche Zentrum fur Luft-und Raumfahrt e.V. (DLR, Stade, Germany), the national research center for aeronautics and space, along with Airbus subsidiary Composite Technology Centre GmbH (CTC, Stade), which specializes in composite processing technologies.

Source | Evonik

The study built on findings from a previous 2014 project from CTC, which studied material options for out-of-autoclave (OOA) hand lay-up production of a Dornier 728 nose landing gear door part, and found that Evonik’s PMI foam core sandwiched between carbon fiber/epoxy faceskins was 25% less expensive to produce and weighed 19% less than a carbon fiber/epoxy prepreg and honeycomb core design. The 2019 study set out to automate construction of the Dornier 728 part for high-volume production.

For the new study, carbon fiber/epoxy prepreg sandwich part preforming production trials were successfully carried out on DLR’s EVo plant, which is a highly flexible, fully automated production line. The EVo plant is fitted with conventional vacuum gripper robot arms for handling cut-to-size glass fiber and carbon fiber fabrics, tapes, lightning strike protection meshes and foam cores.

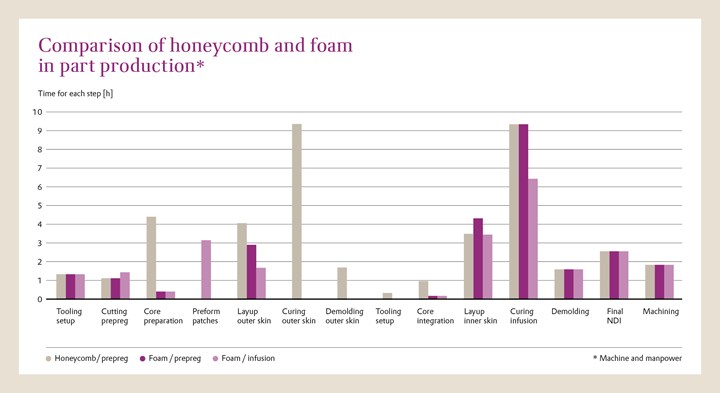

According to Evonik, the study results demonstrated 65% less mold tool utilization time compared to manual production of the same part. For aircraft part manufacturers, this effectively doubles production capacity, providing part output rates that Evonik says are unachievable with a honeycomb core using the same tooling. (See figure below).

Source | Evonik

The EVo plant robot lay-up trial demonstrated that it is possible to use automation to significantly reduce the overall production steps and time needed to manufacture the Dornier 728 nose landing gear door using ROHACELL HERO as the sandwich foam core material instead of an equivalent grade honeycomb core. An additional cost benefit was that EVo’s current automation equipment, which would have needed adaptations to handle a honeycomb core, did not need to be adapted to support the ROHACELL foam core part. Based on mechanical properties from the Fraunhofer IWM Institute in Halle, Germany, Evonik says that ROHACELL HERO also provides the same level of damage resistance and visual inspection detectability as an equivalent aircraft structural grade honeycomb core.

Evonik aims to take these processes and material to high-volume aircraft part production.

Related Content

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreOtto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreRead Next

Scaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read More

.jpg;width=70;height=70;mode=crop)