ATL/AFP

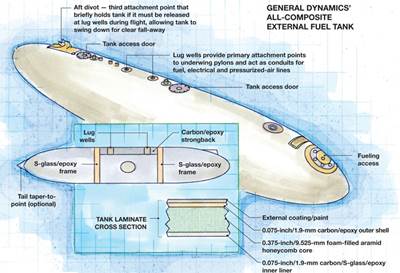

Carrier-capable, all-composite external fuel tank

Legacy product positions builder for a shot at an F-35 contract.

Read MoreStatus update on composites automation

Consultant Carroll Grant reviews progress made in recent years toward greater variety in automated composites processing machine sizes configurations and capabilities.

Read MoreAddressing the cost of aerospace composites

In the aerospace composites industry’s history, millions of research and development (R&D) dollars have been spent addressing cost.

Read MoreGKN A350 spar program update

Automated fiber placement to replace established tape laying/drape forming process for the composite rear spars on the new midsize commercial passenger jet.

Read MoreCorrosion resistance: Desert-bound chemical and potable-water tanks

RL Industries (Fairfield, Ohio) recently overcame logistical obstacles to successfully fabricate five large composite storage tanks for a chemical plant in Saudi Arabia.

Read MoreDeepsea submersible incorporates composite pressure capsule

Spencer Composites Corp. (Sacramento, Calif.) fabricates the inner carbon/epoxy composite pressure capsule for a submersible deepsea vessel the late Steve Fossett was to take to the depths of the Pacific Ocean's Mariana Trench.

Read MoreFilament wound pipe proves durable in electric power plants

Korea-based Hankuk Fiber Glass Co. Ltd. develops a much more durable composite alternative to cast iron ash-transfer pipes for coal-burning electric power plant customers.

Read MoreAutomating wind blade manufacture

Recent technology announcements portend a new era of more efficient blade production.

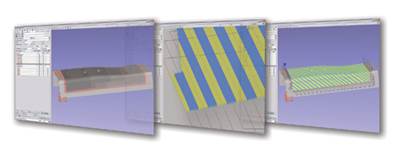

Read MoreAFP/ATL design-to-manufacture: Bridging the gap

Managing production of a structure made via fiber or tape placement often requires software-aided manipulation of the subtle differences between that which is designed and that which can be manufactured.

Read MoreNew packaging machine uses lightweight carbon fiber airshafts

When Premier Paper Converting Machinery (New Berlin, Wis.) introduced its new custom machine for producing Kraft paper honeycomb used to make packaging materials, the device was equipped to hold four massive 98-inch/2.4m wide rolls of paper, each one weighing 5,300 lb/2,409 kg. To support these paper rolls during u

Read More