ATL/AFP

Automated, in-situ inspection a necessity for next-gen aerospace

Inline inspection technologies continue to evolve with the aim of providing faster and more accurate part inspection.

Read MoreSpirit AeroSystems invests in qualification program with Toray prepreg

The world’s largest aerospace tier supplier seizes the opportunity to develop its own allowables for a carbon fiber prepreg, setting an important precedent.

Read MoreLarge, high-volume, infused composite structures on the aerospace horizon

Infused carbon fiber composite structures are not new, but they have never been built at the rates anticipated for next-generation, single-aisle aircraft. It is a daunting prospect — but a feasible one.

Read MorePlant Tour: STELIA Aerospace, Méaulte, France

Supplier of Airbus fuselage sections pushes boundaries of hybrid aerostructures production, assembly and thermoplastic composites.

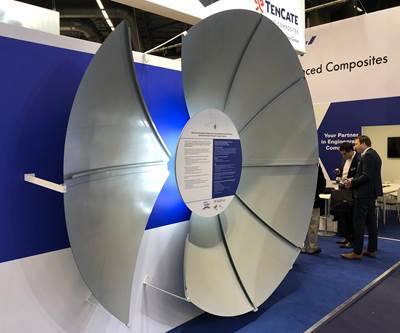

Read MoreThermoplastic composites: Poised to step forward

The evolving role of thermoplastic materials and processes and their future in next-generation commercial aircraft.

Read MoreWeb Industries releases brochures highlighting aerospace composites solutions

The downloadable brochures highlight Web’s automation development center and its suite of aerospace solutions.

Read MoreNIAR begins construction on new ATL, AFP lab

The Advanced Laboratory for Aerospace System (ATLAS) will develop manufacturing protocols for automated fiber placement (AFP) and automated tape laying (ATL) for aircraft systems.

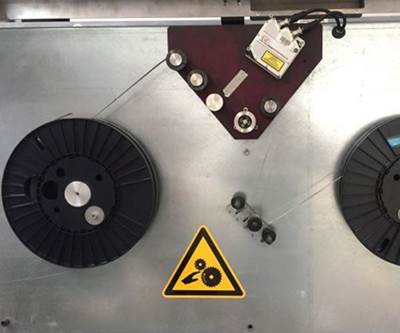

Read MoreMeasuring thermoplastic prepreg tape quality for part process control

Low-cost tests measuring dimensions, thermal behavior and consolidation predict CFRTP part quality.

Read MoreTxV Aero Composites complies with AS9100 standards

The aerospace supplier has received AS9100 and ISO 9001:2015 certifications for its automated thermoplastic composite part manufacturing facility.

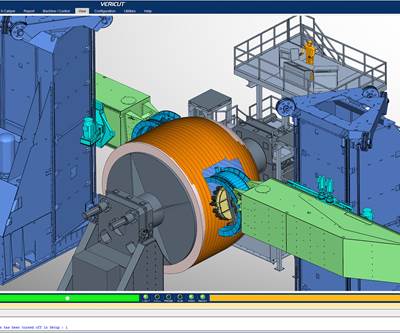

Read MoreSmarter, integrated data for ATL/AFP

More than helping to eliminate dry runs and costly errors, AFP/ATL software is beginning to benefit the whole product lifecycle through the interconnectedness of the digital thread.

Read More