Broetje-Automation GmbH

Am Autobahnkreuz 14

Rastede, D-26180 DE

49 4402 966 0

info@broetje-automation.de

About Broetje-Automation GmbH

IS THIS YOUR COMPANY?

As Seen On ÂÌñÏ×ÆÞ

Broetje-Automation GmbH Supplies the Following Products

- Composites Materials Handling

- Composites Process Development

- Robots

Editorial, News, and Products

-

Smart composites equipment advances aerocomposites innovation

CAMX 2025: From fiber to flight, Broetje-Automation innovates composites manufacturing with integrated AFP, drilling and sealing technologies.

-

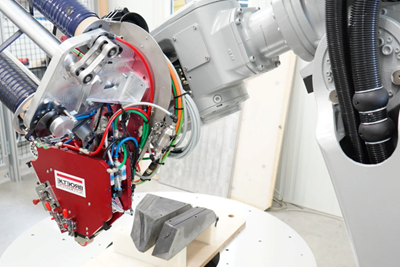

RoMaNi 2 project enhances industrial robot flexibility for composites, metals machining

Newly developed milling kinematics on a linear axis enables versatile and efficient machining with up to 0.1-millimeter production tolerance.

-

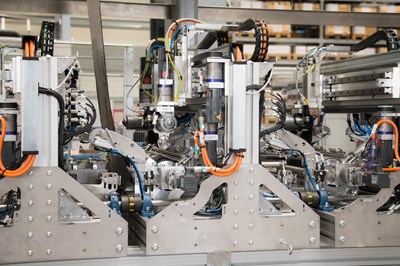

Broetje-Automation, Spirit complete CCPS project for automating aircraft preform production

Continuous composite preforming system (CCPS) integrates all work steps, from the roll to the stringer, in a fully automated, smaller footprint process, taking the next step for future aircraft programs.

-

Broetje-Automation demonstrates rCF placement via AFP

Through the ScrapSeRO project, the system integrator and machine builder successfully processed recycled composites, in addition to more traditional materials, via its highly flexible Staxx One system.

-

Broetje-Automation presents automated sealing solutions for aerocomposites

Versatile and precise system options, whether semi- or fully automated, can be tailored to individual process requirements for composite or metallic materials, ultimately reducing process steps, labor hours and cost.

-

JEC World 2023 preview: Broetje-Automation

The STAXX One automated fiber placement (AFP) systems are run by industrial robotics and incorporate digital twin technology.

-

Broetje-Automation works with Boeing Germany, consortium in “Shimless Assembly” project

Foundation for future aircraft programs aims for -75% manufacturing time, -25% cost via end-to-end digitization, tolerance compensation and force-controlled joining.

-

JEC World reveals 2022 Innovation Awards finalists

Innovation Awards celebrate successful projects and fostered cooperation between players in the composite industry, with 30 finalists in ten categories.

-

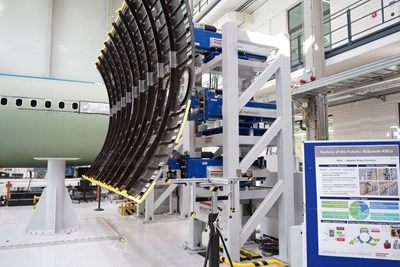

Broetje-Automation delivers EcoPositioners for automated built-in stress-compliant joining in aircraft fuselages

Modularized and highly precise positioning system increases assembly accuracy and speed, enables digitization of CFRP aircraft components assembly for factory of the future.

-

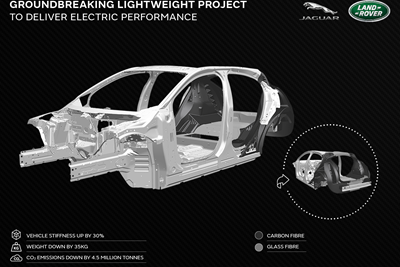

Jaguar Land Rover composites project to advance EV lightweighting, reduce emissions

Four-year Tucana project aims to increase vehicle stiffness by 30% cut weight by 35 kilograms, refine crash safety via tailored composites for 2022 prototype fleet.

-

M-Technologie rebrands as SA France S.A.S

The Broetje-Automation Group subsidiary rebranding is a strategic approach to better leverage the Group’s aerospace know-how for the European market.

-

Update: Lower wing skin, Wing of Tomorrow

Airbus is evaluating several advanced composites technologies as part of its Wing of Tomorrow program. Among these is liquid resin infusion of the lower wing skin, being developed by Spirit AeroSystems.

-

Broetje-Automation presents automated sealer for aircraft components.

The automated, modular system enables clean, safe and speedy production for all aircraft component sealing.

-

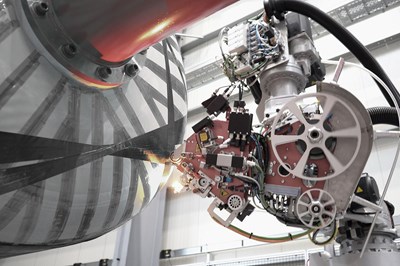

Modular, mobile, multiple robotics poised to change the AFP/ATL paradigm

The German Aerospace Center (DLR) is working on two multi-robot automated fiber and tape placement technologies that could change the paradigm in large-part aerocomposites manufacturing.

-

Research project claims CFRP part production at half cost, faster throughput

The iComposite 4.0 project, led by Schuler AG and its partners, has tested its new production process with carbon fiber-reinforced plastic automotive prototype parts.

-

Broetje-Automation to establish U.S. headquarters in Chicago

Long-term lease with Elk Grove Technology Park is part of the company’s plans for an increased footprint in the North American market.

-

Broetje-Automation enlarges AFP portfolio for serial composite production

The STAXX product line of automated fiber placement (AFP) machining centers is designed for both thermoplastic and thermoset composite applications.

-

Thermoplastic overmolded thermosets, 2-minute cycle, one cell

Adhesive-free, functionalized hybrid composites enabled by industry-first, integrated molding cell.

-

Preforming goes industrial: Part 1

ATL and AFP-based preforming options now abound for processing dry and/or impregnated reinforcements as quickly as 1 minute or less with potential yearly part yields in the millions.

-

Automated Preforming, Part 1: Numbers and Landscape

CW’s multi-blog series on preforming begins with an overview and quick look at the numbers: 1-minute take time, 10-15 seconds per layer, 490-kg/hr and 3.5 million parts/year. Are you ready for serial CFRP production?

-

GKN A350 spar program update

Automated fiber placement to replace established tape laying/drape forming process for the composite rear spars on the new midsize commercial passenger jet.