JEC World 2023 preview: Broetje-Automation

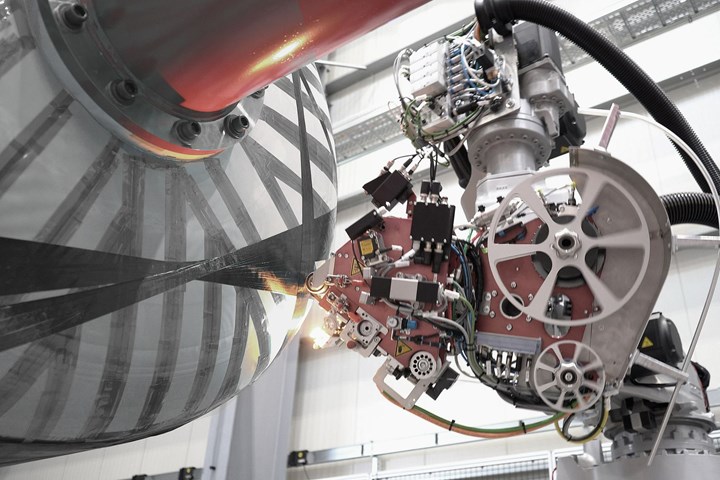

The STAXX One automated fiber placement (AFP) systems are run by industrial robotics and incorporate digital twin technology.

Broetje-Automation GmbH’s (Rastede, Germany) STAXX One automated fiber placement (AFP) systems are suited for a variety of composite structures.

Broetje-Automation GmbH recently announced the delivery of a STAXX One AFP system to VIC-K (Houston, Texas, U.S.), an international provider of products and services to the aerospace, defense, energy and rail sectors. The system is said to include a Comau (Grugliasco, Italy) industrial robot with a STAXX One fiber placement end effector and an additional rotational axis, making it ideally suited for building a variety of composite structures.

The system’s Siemens (Alpharetta, Ga., U.S.) NC Controls and modular cell concept are marketed to offer product flexibility combined with industrial readiness, enabling efficient production and cost-effective development. The system also features digital twin capability, which enhances its efficiency, and includes a CAM system for offline programming based on 3D/2D CAD data, collision analysis, and simulation for both machine and layup concept.

VIC-K will operate the STAXX One system in partnership with its customer in South Korea.

“The STAXX One automated fiber placement system is a state-of-the-art technology that enables efficient and cost-effective production of composite structures. We are confident that VIC-K will benefit greatly from this system’s exceptional product flexibility, industrial readiness, and digital twin capability,” says Jonas Wermter, key account manager at Broetje-Automation.

At JEC World 2023, Broetje-Automation GmbH is exhibiting in Hall 5, Stand N82.

Related Content

-

How AI is improving composites operations and factory sustainability

Workforce pain points and various logistical challenges are putting operations resilience and flexibility to the test, but Industry 4.0 advancements could be the key to composites manufacturers’ transformation.

-

ASCEND program completion: Transforming the U.K.'s high-rate composites manufacturing capability

GKN Aerospace, McLaren Automotive and U.K. partners chart the final chapter of the 4-year, £39.6 million ASCEND program, which accomplished significant progress in high-rate production, Industry 4.0 and sustainable composites manufacturing.

-

SAM XL demonstrates closed-loop digital methodologies via full-size aerocomposite parts development

PeneloPe Project’s modular, zero-defect manufacturing deliverables are being highlighted in an upcoming video that demonstrates the resulting aerospace pilot line’s feasibility.

.jpg;width=70;height=70;mode=crop)