Search Results

Showing 71 – 80 of 2863 results

Filament winding is a specialized technique used in composite manufacturing, involving the precise and automated winding of continuous fibers onto a rotating mandrel or mold. This method allows for the creation of strong and seamless structures, optimizing the alignment and orientation of the fibers to meet specific design requirements. Filament winding is employed in producing cylindrical or conical composite parts, such as pipes, pressure vessels, and aerospace components, enabling engineers to tailor the strength, stiffness, and performance characteristics of the final product.

Processes in composites manufacturing encompass a diverse array of techniques employed to fabricate composite materials. These processes include methods like hand layup, where layers of resin and reinforcement materials are manually placed, and vacuum infusion, where a vacuum draws resin into a preform. Other techniques like compression molding, filament winding, and automated methods such as 3D printing are utilized to create intricate and specialized composite structures. Each process offers unique advantages in terms of precision, scalability, and efficiency, catering to diverse industry needs. As technology advances, newer methods are emerging, promising faster production cycles, reduced waste, and increased customization, driving the evolution of composite manufacturing towards more sophisticated and versatile methodologies.

The wind energy market has long been considered the world’s largest market, by volume, for glass fiber-reinforced polymer (GFRP) composites — and increasingly, carbon fiber composites — as larger turbines and longer wind blades are developed, requiring higher performance, lighter weight materials. The outer skins of wind and tidal turbine blades generally comprise infused, GFRP laminates sandwiching foam core. Inside the blade, rib-like shear webs bonded to spar caps reinforce the structure. Spar caps are often made from GFRP or, as blade lengths lengthen, pultruded carbon fiber for additional strength.

French startup Energiestro’s prototype solar energy flywheel-based storage system aims to reduce costs with glass fiber composites and prestressed concrete.

EU project will develop bio-based, repairable and recyclable vitrimer composites and advanced sensors for highly reliable, sustainable wind blades.

JEC World 2025: CompoTech PLUS is recognizing three decades serving the composites industry, highlighting latest material and fiber winding technology developments.

Exel adapted carbon fiber profiles originally designed for wind turbines to meet the low-drag, high-flexibility and long-term fatigue performance demands of this renewable energy system’s nature-inspired membrane.

The 130-megawatt utility-scale wind farm off the coast of Long Island leads state efforts to install 9 gigawatts of offshore wind by 2035.

Carbon and glass fiber plug-and-play wind propulsion system will support DGAMPA’s maritime decarbonization goals.

Carbon fiber-reinforced epoxy composites are key to building these long-lasting wind propulsion technologies for energy-efficient watercraft.

FLOWIN cash prize and technical assistance will enable Principle Power and Aker Solutions to explore ways to serialize fabrication, deploy its offshore wind platform for the U.S.

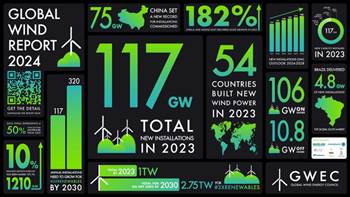

Global Wind Report describes a record year for wind energy in 2023, but highlights the need for policy-driven action to meet COP28 and 1.5°C pathway targets.

Pioneer in mandrel-based reinforced rubber and composite products, TANIQ offers TaniqWindPro software and robotic winding expertise for composite pressure vessels and more.