The Gill Corp. announces hybrid laminate for aircraft cargo flooring

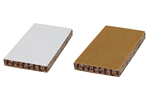

Gillfab F433F is a fiberglass-reinforced epoxy laminate with aluminum bonded faces, offering enhanced durability, fire resistance and strength.

Source | The Gill Corp.

The Gill Corp. (El Monte, Calif., U.S.) introduces Gillfab 5433F, a lightweight hybrid laminate material designed specifically for the rigorous conditions found in aircraft cargo areas. The material features aluminum faces bonded with an epoxy laminate, fortified by woven fiberglass, providing optimal resilience in high-traffic zones such as around cargo doors and within bulk cargo sections.

According to the company, Gillfab 5433F is engineered to be highly resistant to physical damage, including dents, punctures and abrasions, to provide enduring performance under tough conditions. Moreover, it offers improved load-bearing capacity, maintaining structural integrity even when subjected to heavy loads. Enhanced aircraft safety is achieved by retarding fire spread, providing crucial additional time for emergency procedures; Gillfab 5433F meets the stringent requirements of FAR 25.853 and 25.855 Appendix F Part 1, thereby meeting aviation industry standards for safety and performance.

Related Content

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

Plant tour: Collins Aerospace, Riverside, Calif., U.S. and Almere, Netherlands

Composite Tier 1’s long history, acquisition of stamped parts pioneer Dutch Thermoplastic Components, advances roadmap for growth in thermoplastic composite parts.