Teijin unveils novel spread-tow carbon fiber woven fabric

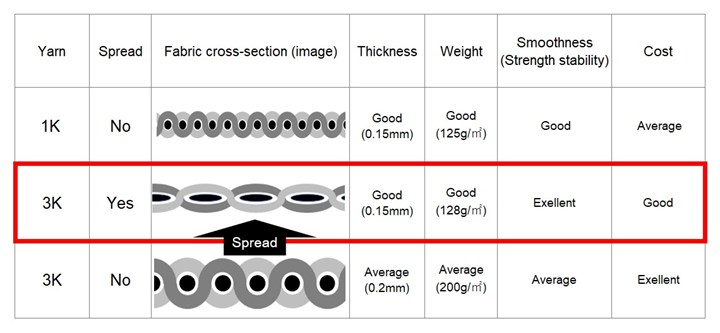

3K woven fabric developed via Teijin’s tow-spreading technology is as thin as 1K wovens and nearly the same weight, but is said to require less cost to produce, and offers better strength stability.

Photo Credit: Teijin Ltd.

Teijin (Tokyo, Japan) has launched a lightweight, strong and cost-effective carbon fiber woven fabric developed with the company’s proprietary tow-spreading technology.

The new woven fabric is made with 3K (3,000) carbon fiber filament yarn for applications requiring low weight and design flexibility, such as automotive interior materials and sporting goods. Teijin, using its in-house tow-spreading technology, succeeded in thinning the 3K fabric from a molding thickness of 0.2 mm to approximately 0.15 mm, the same as that of 1K woven fabric, when molded into carbon fiber-reinforced plastic (CFRP).

Thanks to the flat undulations of the fabric’s intersecting yarns, CFRP made with Teijin’s new fabric is said to offer improved smoothness. This, according to Teijin’s in-house research, results in more stable strength compared to CFRP made with 1K carbon fiber woven fabric. In addition, the company says its proprietary tow-spreading technology lowers the fabric cost below that of conventional 1K woven fabric, and, despite using 3K yarn (200g/m2), Teijin reduced the weight by 35%, similar to fabric made with 1K yarn (125g/m2).

Teijin plans to market the woven fabric to manufacturers of industrial and sports products. Together, with the other spread-tow carbon fiber woven fabrics in the Teijin portfolio, the company is targeting sales of JPY 2 billion (approx. $17.4 million) in fiscal 2030.

Related Content

-

Plant tour: Collins Aerospace, Riverside, Calif., U.S. and Almere, Netherlands

Composite Tier 1’s long history, acquisition of stamped parts pioneer Dutch Thermoplastic Components, advances roadmap for growth in thermoplastic composite parts.

-

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

-

Development of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.