Kane Robotics introduces low-cost automation for composite bond preparation

Collaborative robots use algorithm-based quality inspection systems to automate assembly and finishing processes for composite aerospace structures.

Source | Kane Robotics

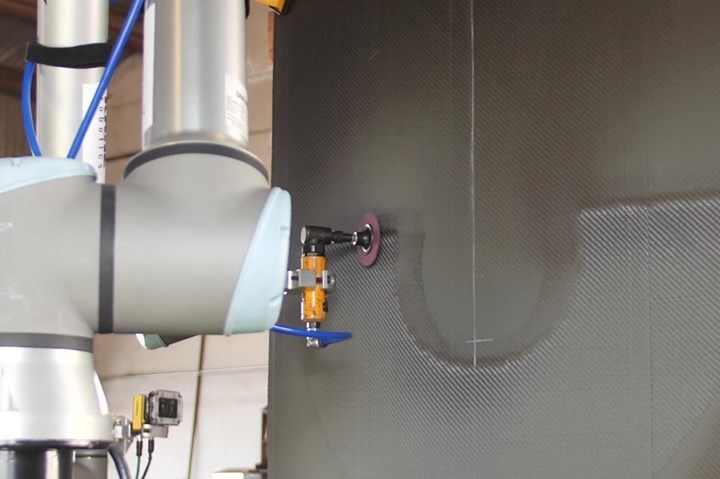

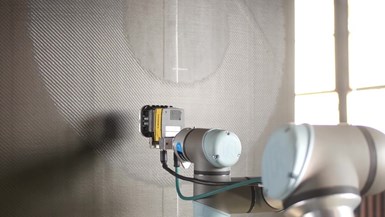

(Albuquerque, N.M., and Chino, Calif., U.S.) has developed mobile, collaborative robot (cobot)-based automation systems to perform abrasive material removal and surface preparation of structures in a variety of materials, including carbon fiber-reinforced epoxy.

Cobots, an alternative to traditional, autonomous industrial robots, are a lower-cost, lightweight class of robots intended to interact with humans in a shared space or to work safely in close proximity. According to Kane Robotics, cobot systems offer the opportunity to implement an automated process and realize the benefits for less than a tenth of the cost of an industrial robot, or about the annual cost of a skilled technician.

With its automation systems, the company is targeting processes that are currently being performed manually, following an 80/20 rule for automating tasks — in other words, automating 80% of a task so that the existing skilled technician can perform the more complex or skilled parts of the tasks.

Source | Kane Robotics

According to Kane Robotics, its low-cost automation systems are particularly suitable for assembly and finishing processes, such as drilling, or dispensing of adhesives, liquid shim and sealants, for the fabrication of aerospace composite structures. From abrasive material removal for finishing, critical surface preparation for bonded surfaces and finishing processes such as painting, bonding of ablative material or a radar-absorbing material, the company says that millions of square feet of composite surfaces are currently finished or assembled by hand every day.

Liquid shimming, paste adhesives and sealants are said to be ideal candidates for cobot-based dispensing systems, as well as lightweight drilling and countersinking with jigs and templates.

Kane Robotics’ cobots use CAD data to define robot arm paths and are process trained, starting with the manual operations. Refinements are made as the robot performs the process to produce the desired results.

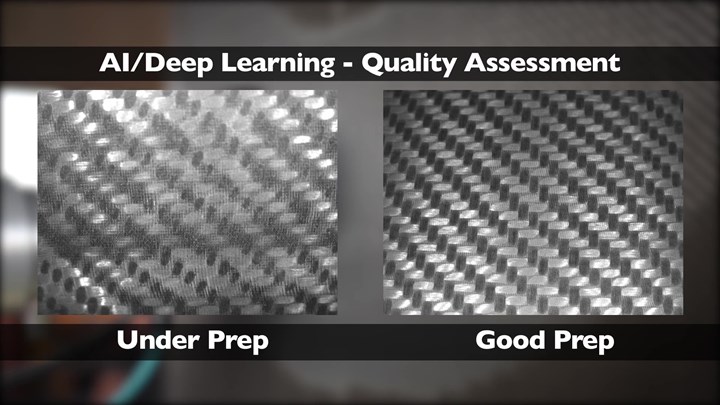

To date, the company has demonstrated a machine learning algorithm using a Cognex camera and software. Material removal levels from under-prepped conditions to over-prepped conditions were documented and used to teach the system what the ideal surface should look like (see image below). Once taught, the system was used to inspect, verify and document the surface condition after sanding.

Source | Kane Robotics

Future plans, the company says, include in situ, real-time inspection and artificial intelligence algorithms to classify the surface condition, as well as those to instruct the robot to sand until the proper surface condition has been reached.

For more information, visit .

Related Content

-

Aitiip concludes HELACS project with waterjet cutting demonstration

Novel platform involving digital twin and human-robot collaboration succeeded in cutting a component from the 19th section of an A350 wing, highlighting its ability to enable composite structure recycling.

-

ST Engineering MRAS presents initiatives to drive autoclave efficiency, automation

During a JEC World 2024 panel discussion, the company revealed ways in which it is maximizing throughput and efficiency of its autoclaves and enhancing composites production processes.

-

How AI is improving composites operations and factory sustainability

Workforce pain points and various logistical challenges are putting operations resilience and flexibility to the test, but Industry 4.0 advancements could be the key to composites manufacturers’ transformation.

.jpg;width=70;height=70;mode=crop)