Hexcel low-temp-cure adhesive targets marine applications

Hexcel has launched its new low-temperature, fast-cure HexBond 679 adhesive film.

Hexcel (Stamford, Conn., U.S.) has launched its new low-temperature, fast-cure HexBond 679 adhesive film. HexBond 679, says Hexcel, delivers strong bonding performance in sandwich structures and offers significant cycle time reductions with its short-cure cycles at low temperatures. Formulated specifically to meet the low-temperature cure requirements of marine and industrial applications, HexBond 679 is a 250-gsm supported epoxy adhesive film that is fully compatible with the HexPly M79 prepreg range. Curing in four hours at 80ËšC/176ËšF or eight hours at 70ËšC/158ËšF, HexBond 679 films are said to provide extremely high lap shear and peel strength performance, as well as shelf-life of up to six weeks at 23ËšC.

Hexcel says HexPly M79 prepregs and HexBond 679 adhesive films allow boatbuilders to increase build rates with reduced heating and cooling times. When combined with Hexcel’s air venting Grid Technology HexPly M79, UD carbon tapes can be laminated with reduced debulking steps to produce porosity of <1%, regardless of laminate thickness.

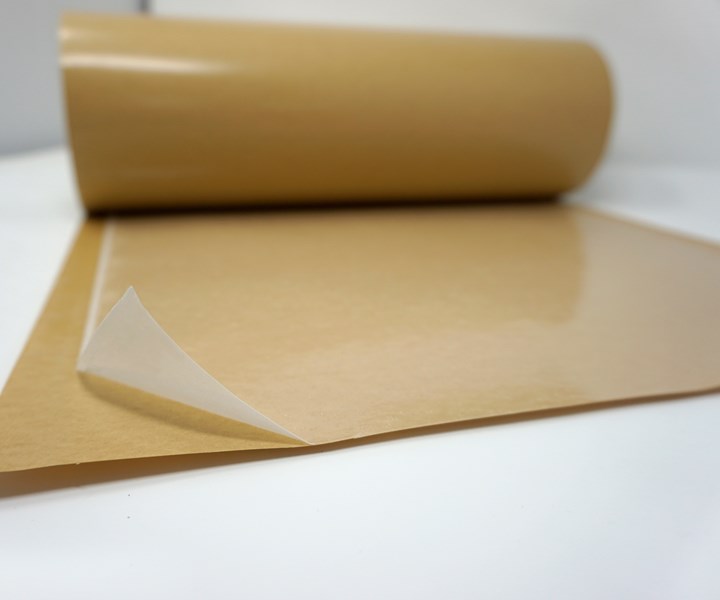

Hexcel HexBond 679 film adhesive. Source | Hexcel

HexBond 679 adhesive film has also received DNV-GL Type approval as part of Hexcel’s latest accreditation program, providing vessel manufacturers with additional independent assurance of the product’s quality, performance, and consistency.

Related Content

-

The next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

-

Reinforcing hollow, 3D printed parts with continuous fiber composites

Spanish startup Reinforce3D’s continuous fiber injection process (CFIP) involves injection of fibers and liquid resin into hollow parts made from any material. Potential applications include sporting goods, aerospace and automotive components, and more.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.