CAMX 2022 exhibit preview: Microtex Composites

Microtex Composites presents Microtex-Style, a new composite fabric option to support creative part and structure customization for industry customers.

Photo Credit: Microtex Composites

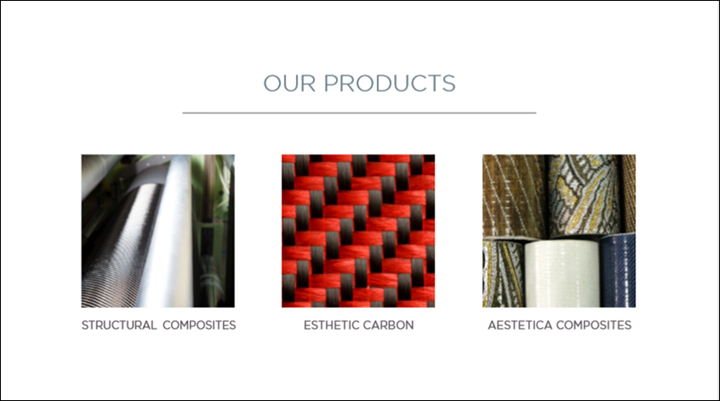

Microtex Composites Srl (Prato, Italy) is a European company specializing in the manufacture of advanced carbon fiber composites — dry and prepreg — which are widely used for structural parts, exterior panels and a carbon fiber look for interiors in the motorsports, automotive, marine, transportation and consumer industry markets. The company, which boasts chemical research laboratories for R&D activities, is also equipped with solvent impregnation, hotmelt and unidirectional (UD) tape production lines.

The company presents Microtex-Style at CAMX, said to be a new vision of fabric customization. The company is able to apply a careful study of patterns combined with the use of both fancy and technical yarns. Ongoing research aims to seek out new material inspirations to propose to customers.

Customized fabrics that Microtex can produce on customer request include:

- Microtex-Customized

- Tailor-made fabric

- Tailor-made style (TMS)

- Microtex tailor

- Your tailor-made fabric (YTMF)

- Your customized style (fabric) (YCS)

- Tailor-tex

- Fab-tex

- Fab fabric

Microtex says its fabrics are made of high-performance impregnated yarns that comply with aging tests. Raw materials used include carbon, glass and aramid fibers, linen and other high-performance fibers. The company’s quality system is certified under ISO 9001:2015 and IATF 16949:16.

Microtex Composites’ team of expert technicians and engineers manage the entire production process to ensure the customer’s concept is implemented to the highest quality standards. The final result will not only focus on performance, the company says; its Style Office also creatively customizes the result according to a customer’s needs.

A recent cooperation between Microtex Composites’ R&D department and Automobili Pininfarina’s (Munich, Germany) Colour Materials office developed two carbon fiber fabrics (GG 245 6100 and GP 260 2100) exclusively produced for the Battista Italian sports car. The fabrics are characterized by distinctive patterns, with one enriched by blue yarn and use Microtex’s X4-140 matrix, which is said to enable excellent performance features such as maximum transparency and an improved surface finishing. Moreover, the matrix is “dicy-free” meaning there will be no white spots and marks when in contact with the mold.

Related Content

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.