CAMX 2019 exhibit preview: MultiMechanics

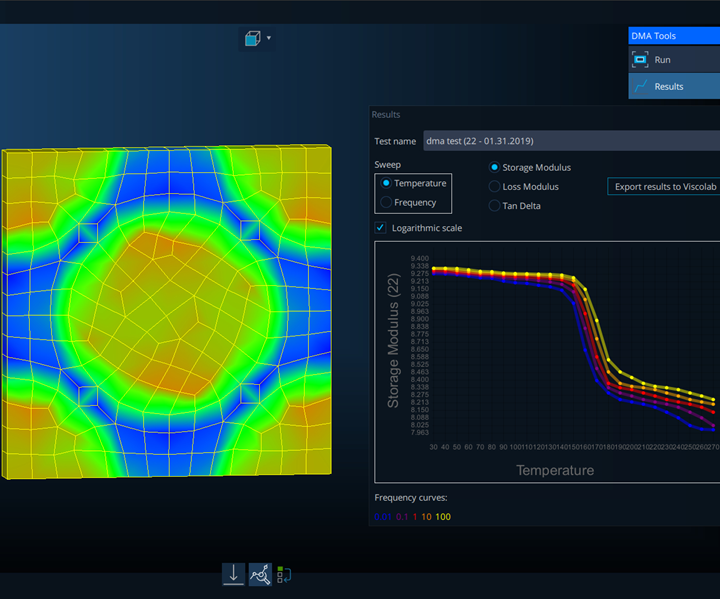

MultiMechanics is showcasing its MultiMech 19.0 composite modeling and simulation software.

Source | MultiMechanics

MultiMechanics (Omaha, Neb., U.S.) is showcasing its MultiMech 19.0 composite modeling and simulation software. Released in March of this year, MultiMech 19.0 features include:

- a new bi-modulus elastic model to enable engineers to better capture the mechanical behavior of carbon fibers,

- virtual DMA to more easily characterize the viscoelastic behavior of complex microstructures,

- parallel runs in Optimizer mode to reduce the job runtime,

- new material and failure models, including continuum damage models for orthotropic materials and new damage laws enabling users to capture unique material behavior with higher accuracy,

- enhancements to linear solver, including improved automated time step and optional displacement convergence check, as well as the ability to check for large displacements in the nonlinear solver, and

- a redesign of the material database and enhancements to speed up the workflow.

Related Content

-

Put your research in the spotlight with CAMX Poster Sessions

Researchers, engineers and industry professionals are now able to submit abstracts for CAMX 2025 Poster Sessions until May 30.

-

LFAM specialization caters to 3D printed composite tooling, molds

CAMX 2025: AES is committed to driving technological advancement and application development in 3D printing, distinguishing its diverse capabilities through several tooling examples.

-

Noncontact optical strain gage delivers complete 3D surface measurement insight

CAMX 2025: The Aramis system by Trilion, based on DIC and photogrammetry technology, performs high-precision measurements in the sub-micrometer range, across a wide range of testing environments and material types.

.jpg;width=70;height=70;mode=crop)