CAMX 2019 exhibit preview: Goodwinds Composites

Goodwinds Composites will showcase its micro-pultruded carbon rods, wrapped carbon tubes, and composites machining capabilities at CAMX 2019.

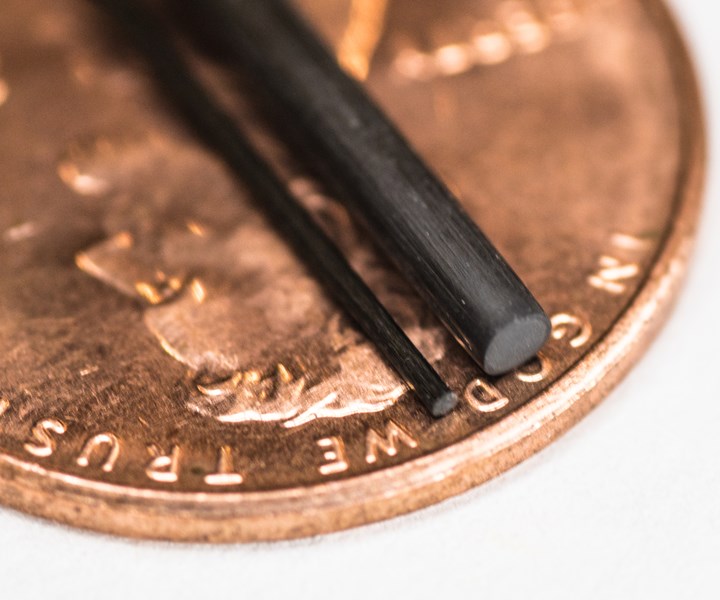

Micro-pultruded carbon rods

Source | Goodwinds Composites

Goodwinds Composites (Mount Vernon, Wash., U.S.) will showcase its micro-pultruded carbon rods, wrapped carbon tubes, and composites machining capabilities at CAMX 2019 (Booth Z46), September 23-26, in Anaheim, Calif.

The micro-pultruded carbon rods are produced in short runs and can have a diameter as small as .020 inches. Frequently used for z-axis reinforcement of laminate stacks, Goodwinds Composites’ micro carbon has all the attributes of larger pultruded carbon rods such as excellent stiffness-to-weight ratio and high Fiber volume Fraction. Additionally, tooling costs for custom micro-pultruded rods are relatively low.

Goodwinds Composites’ wrapped carbon tubes can be found in guitars, tents, backpacks, hiking poles, pool cues and the NASA Mars Helicopter. Goodwinds Composites is well-versed in metrology and can precisely and repeatedly machine composite rods and tubes to tight tolerances. The company’s capabilities include notching, milling, drilling, sanding, cutting and grinding to specific outer diameters.

Related Content

-

Highly tunable, woven lattice reinforcements target automotive structures

CAMX 2023: Startup Weav3D will be demonstrating its two collaborative automotive demonstrator parts and present two conference papers.

-

TPC, FRP poles and fire-retardant panels

CAMX 2025: Avient Corp. is bringing its latest composites innovations including Polystrand, GridCore and Hammerhead solutions.

-

Autonomous agents optimize decision flows in aerospace, composites production

CAMX 2025: With manufacturers face labor shortages, increasing product complexity and pressure to operate sustainably, Plataine’s AI Agents provide the agility and intelligence needed for real-time decision-making.