ThermHex, Brixtone complete honeycomb core panel production for 400 commercial vans

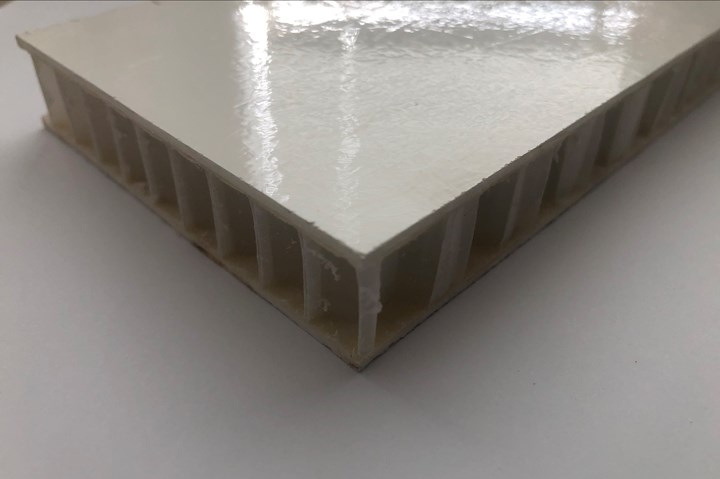

Cargopan wall panels incorporate ThermHex polypropylene honeycomb core for increased robustness damage resistance, waterproofing and a tripled lifespan.

Photo Credit: Brixtone

ThermHex Waben GmbH (Halle, Germany), a producer of honeycomb cores for sandwich panels and parts, and Brixtone (Poland), production specialist for composite sandwich panels, have completed the production of triple-life wall panels for 400 commercial vans.

Brixtone’s Cargopan wall panels use ThermHex polypropylene (PP) honeycomb panels with a skin. Said to have triple the lifespan compared to other panels on the market, ThermHex notes Cargopan’s robustness and rigidity — a result of its material use and honeycomb structure — makes it more resistant to damage in case of collisions. The wall panels are also more waterproof. These properties reportedly make them ideal for walls of commercial vehicles, and have been used by van manufacturers such as Renault (Boulogne-Billancourt, France) and Iveco (Turin, Italy).

“We have had such success with Cargopan due to the durability, rigidity and waterproofing — it moves the world of wall panels for commercial vans up a league,” says PaweÅ‚ Faszcza of Brixtone. “It stands out because it is such a unique product which uses world-class technology.”

According to ThermHex, its polypropylene (PP) honeycomb cores are used wherever high-quality products with an optimum strength-to-weight ratio are required. This includes automotive (see “ThermHex honeycomb core insulates 2,000 camper van elevated roofs”), marine — such as boats, yachts and shipbuilding — interior and furniture, building and construction, wind and solar energy, even swimming pools and prefabricated bathrooms. Additionally, ThermHex now produces all honeycomb cores via renewable energy.

ThermHex Waben GmbH started its production in 2010 and is a licensee of EconCore NV (Belgium), the technology leader for cost-efficient sandwich material production technologies.

Related Content

-

SMC composites progress BinC solar electric vehicles

In an interview with one of Aptera’s co-founders, CW sheds light on the inspiration behind the crowd-funded solar electric vehicle, its body in carbon (BinC) and how composite materials are playing a role in its design.

-

JEC World 2024 highlights: Glass fiber recycling, biocomposites and more

CW technical editor Hannah Mason discusses trends seen at this year’s JEC World trade show, including sustainability-focused technologies and commitments, the Paris Olympics amongst other topics.

-

Co-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.