Teijin Ltd. expands thermoplastic prepreg lineup

CFRTP intermediate materials are now offered with PP, PC and PA matrices, which will now be used as base resins for existing prepreg products.

Photo Credit: Teijin Ltd.

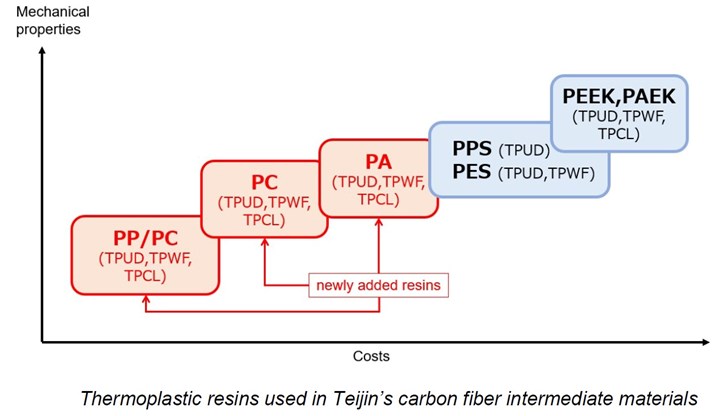

On Feb. 16 Teijin Ltd. (Tokyo, Japan) announced that it has expanded its lineup of carbon fiber thermoplastic intermediate materials with three matrix resins: polypropylene (PP)/polycarbonate (PC) and polyamide (PA). The new resins are now being used as base resins in new versions of the company’s existing prepreg products, including Tenax ThermoPlastic UniDirectional (TPUD), Tenax ThermoPlastic Woven Fabric (TPWF) and Tenax ThermoPlastic Consolidated Laminate (TPCL).

Compared to Teijin’s existing thermoplastic intermediate materials made with polyetheretherketone (PEEK), polyaryletherketone (PAEK), polyphenylene sulfide (PPS) or polyethersulfone (PSE) resins, Teijin says the prepregs made with the three new thermoplastic resins can be molded at lower temperatures for faster and more cost-effective production, making them ideal for applications requiring production efficiency, such as automobiles, sporting goods and precision instruments.

In addition, Teijin is developing new carbon fiber intermediate materials to strengthen its ability to meet diverse customer needs and to continue pursuing its long-term vision for a more sustainable world.

Related Content

-

Otto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.

-

Filament winding increases access to high-performance composite prostheses

Steptics industrializes production of CFRP prostheses, enabling hundreds of parts/day and 50% lower cost.

-

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.