Teijin to carry out life cycle assessment of carbon fiber

Life cycle assessment (LCA) will aid in calculating carbon emissions for all of its carbon fiber filament applications.

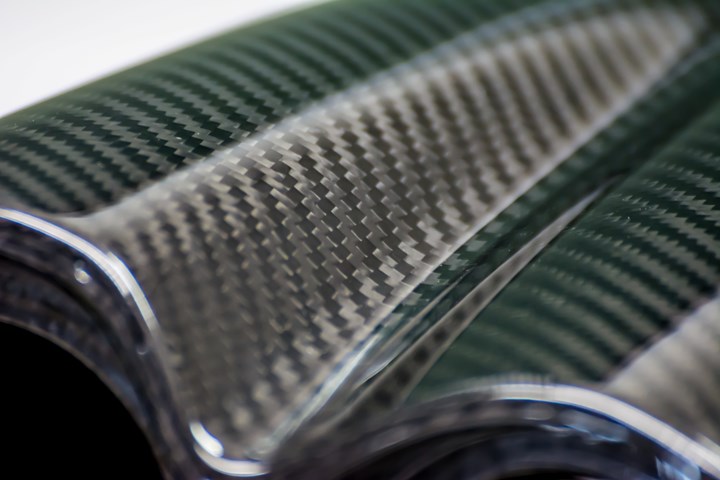

Photo Credit: Getty Images

Teijin Ltd. (Tokyo, Japan) announced on Dec. 15 that it has started to carry out a life cycle assessment (LCA) of its carbon fibers to calculate their total carbon emissions. The company contends that this is an industry first.

Teijin previously calculated the carbon footprint of its carbon fibers used in sports, recreational and industrial applications, and more recently, its carbon fiber filaments used in aircraft applications, which will make it possible to now calculate emissions for all of its carbon fiber filament applications.

Teijin’s LCA methodology has been certified by an independent third-party organization in accordance with ISO14040 and ISO14044 standards and will provide customers with reliable emission data on Teijin’s carbon fiber filaments to help them evaluate their own footprints. The company says its LCA is useful in identifying carbon hotspots in manufacturing processes and evaluating options for emissions reduction.

Looking ahead, Teijin expects to expand its LCA scope beyond carbon fiber filaments to also include intermediate products such as short fibers and prepregs. Furthermore, in cooperation with customers such as final product manufacturers, Teijin eventually plans to evaluate the entire life cycle of its carbon fiber products.

Moreover, the Teijin Group has set climate change mitigation and adaptation as one of the five materialities that it prioritizes as important societal issues. Accordingly, Teijin is striving to reduce its energy consumption and introduce renewable energy and recycling methods, among other initiatives. By further positioning its business to help realize a sustainable circular society, the Teijin Group aims to reduce its group-wide in-house carbon emissions to net zero by 2050.

Related Content

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

Otto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.