Schmidt & Heinzmann selected for TOP 100 Seal 2021 Innovation category

Production machinery and automation solutions company excels in all five category criteria with its innovative initiative implementation and entrepreneurial response to COVID-19.

Photo Credit: Schmidt & Heinzmann

It was reported on Jan. 29 that Schmidt & Heinzmann GmbH & Co. KG (Bruchsal, Germany) has been awarded the on Innovation. Honoring innovative, medium-sized companies, Schmidt & Heinzmann’s achievement marks the 28th time this TOP 100 category has been awarded.

Potential companies are selected through a scientific selection procedure. On behalf of compamedia, the organizer of the TOP 100 innovation competition, innovation researcher Prof. Dr. Nikolaus Franke and his team investigated the innovative strength of Schmidt & Heinzmann. The researchers used around 120 test criteria from five categories: innovation-promotion top management, innovative climate, innovative processes and organization, external orientation/open innovation and innovation success. Due to the current situation, there was also a special part in this round, in which entrepreneurial response to the COVID-19 pandemic was examined.

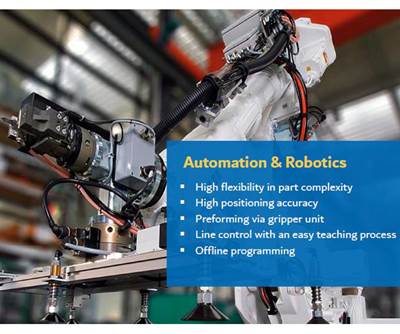

The machine construction company Schmidt & Heinzmann develops and produces tailor-made production machinery and automation solutions for the fiber-reinforced plastics industry. The company has reportedly made a name for itself both nationally and internationally, particularly in the field of sheet molding compound (SMC) semi-finished material production, cutting and stacking, preforming and the automation of pressing processes for the production of composite parts.

The company’s high degree of adaptability and strength also aided it when the COVID-19 situation hit.

“As the world market leader for production machinery and automation solutions in the composites industry, we have to consistently extend our technological lead. We achieve this by consistently supporting the innovative activities of our employees and by regularly informing all colleagues about ongoing innovation projects,” explains Managing Director Matthias Feil.

One way the company says it promotes innovation processes is by implementing a continuous improvement process in which all employees participate. A methodical, systematic and rapid implementation of suggestions for improvement is a matter for each department. “We implement almost 75% of the suggested ideas — this means we can realize huge savings for ourselves and for our customers every year. For example, we were also able to optimize the production of carbon fiber stacks for an automotive manufacturer using innovative processes,” adds Feil.

In order to retain the lead in the industry, the company says it is consistently pushing ahead with its innovation initiatives by cooperating with research institutes or partners from the composite industry. The constant interaction and exchange with customers, and the involvement of the sales team at an early stage of the innovation process, is also said to contribute to the further development of machines and processes that meet and exceed market requirements.

The company’s high degree of adaptability and strength also aided it when the COVID-19 situation hit. From the beginning of the pandemic, Schmidt & Heinzmann reportedly implemented an intercompany information system to inform all employees quickly and concisely about all changes, such as code of conduct and hygiene, home office, dealing with visitors, etc. The system ensures that employees in the home office and on late shift also receive all information promptly and are fully informed.

Further, an immediate risk analysis of the supply chain with weekly updates, increase of inventories in critical product areas, as well as coronavirus-specific sourcing strategies in material procurement ensured a constant supply of materials needed and avoided any production downtime.

By strengthening its locations in China and the U.S., the company says it was also able to counteract travel restrictions at an early stage; this was especially true in the U.S., where employees numbers have increased significantly. As a result, installation, commissioning and service by the local team, in addition to sales, are now ensured.

Related Content

AI-powered robotic solutions support high-mix manufacturing

AI startup offers automation innovations for high-mix, high-variability, manual surface finishing applications.

Read MoreHow AI is improving composites operations and factory sustainability

Workforce pain points and various logistical challenges are putting operations resilience and flexibility to the test, but Industry 4.0 advancements could be the key to composites manufacturers’ transformation.

Read MorePlant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

Read MoreTAVieDA project team cuts aircraft door production time using thermoplastic composites, welding

Fraunhofer groups, Trelleborg and Airbus develop modular, fully automated assembly system concept to replace metals and time-consuming assembly that shows potential for scalability.

Read MoreRead Next

Automating composites production for ease of use and affordability

Schmidt & Heinzemann innovates composites workcells with German quality and small-company flexibility — “modules customized per product and program is the key.”

Read MoreAVK announces winners of 2020 Innovation Awards

Several sustainable composite innovations were recognized and awarded in the Innovative Products/Applications, Innovative Processes and Research and Science categories.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More