Saertex, Safran sign agreement for carbon fiber aircraft equipment production

Under the 10-year contract, Saertex will supply multiaxial carbon fiber fabrics to Safran, to be used to produce engine nacelles for various aircraft.

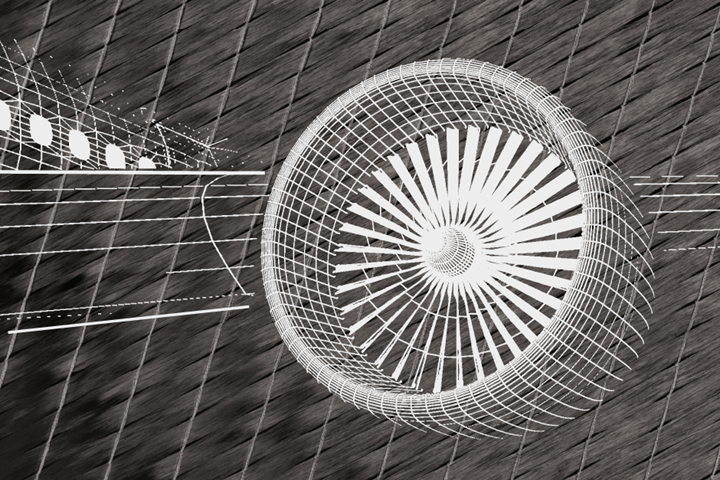

Photo Credit: Saertex

On August 27, Safran Nacelles (Burnley, U.K.) and Saertex GmbH (Saerbeck, Germany) signed a 10-year contract on cooperation for the production of aircraft equipment made of carbon fiber fabrics.

Under the contract, Saertex will supply multiaxial carbon fiber fabrics which Safran will use to produce engine nacelles for various aircraft using infusion technology. This contractual agreement means the cooperation of two globally operating companies.

"I am pleased that, with Safran, we have been able to convince an important new partner of our competence and improved technologies in the aerospace sector,” comments Christoph Geyer, CEO at Saetex at the contract’s conclusion. Similarly, Thierry Viguier, Safran vice president Materials Purchasing voices that Safran is excited for this new partnership.

Related Content

-

Otto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.

-

Low-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.