Saertex supports HyFiVE research project for maritime lightweight construction

Saertex will focus on development of adhesive-free joining technologies and FST-compliant composites for shipbuilding.

Source | Saertex

Saertex (Saerbeck, Germany), a global manufacturer of textile reinforcing materials for lightweight construction, including glass, carbon and aramid fibers, reported on July 1 that it is supporting the BMWi-funded HyFiVE research project and will now focus on hybrid joining technology for maritime use. With Saertex’s support, the project now has five industrial companies and three scientific institutes involved in its development and evaluation of new technologies.

According to Saertex, lightweight construction, as a key technology for sustainable transportation solutions, is difficult to establish in shipbuilding due to inadequate joining technologies between composite materials and steel. Another complicating factor, the company notes, are the high fire protection requirements and the lack of standards for the use of composite materials for ships at sea.

These challenges prompted the HyFiVE research project to bring together relevant companies and institutes to evaluate efficient adhesive-free joining technologies for different applications in shipbuilding, as well as novel processes and methods, all of which will be verified using demonstrators and fire tests. The project’s aim is to meet the time and cost requirements of shipbuilding production and to strengthen the competitiveness of the industry.

In addition to administrative management, Saertex says it will support the project by providing material and engineering in the field of fire protection, with the company’s Leo series and 3D-reinforced Saerfoam products. Specifically, Saertex points to its Leo coated fabric, a fabric equipped with an active fire retardant layer to mitigate fire and to provide component protection.

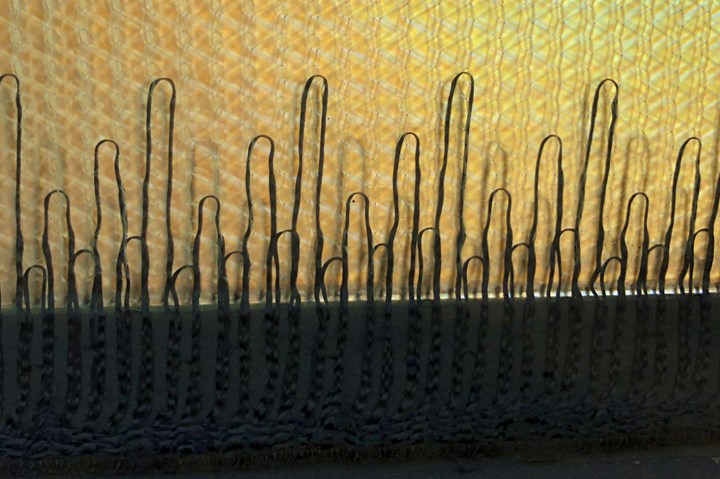

Saerfoam, which can be adapted, will be used as a reinforcing core material, where its mechanical strength properties can be adjusted by selecting the amount and direction of glass bridges through the thickness.

Related Content

-

U.S. Coast Guard MBI releases report on Titan submersible

The two-year investigation into the June 2023 tragedy that took five lives has been published, citing key findings, contributing factors to the casualty and a recommended regulatory framework to avoid future oversight.

-

FIDAMC expands composites R&D into new markets and advanced manufacturing centers

Pioneering technocenter advances RTM, thermoplastic composites, additive manufacturing, microwire, novel lighter weight LSP and more.

-

Revisiting the OceanGate Titan disaster

A year has passed since the tragic loss of the Titan submersible that claimed the lives of five people. What lessons have been learned from the disaster?