Plastic Omnium and Hyliko to decarbonize heavy mobility with hydrogen storage vessels

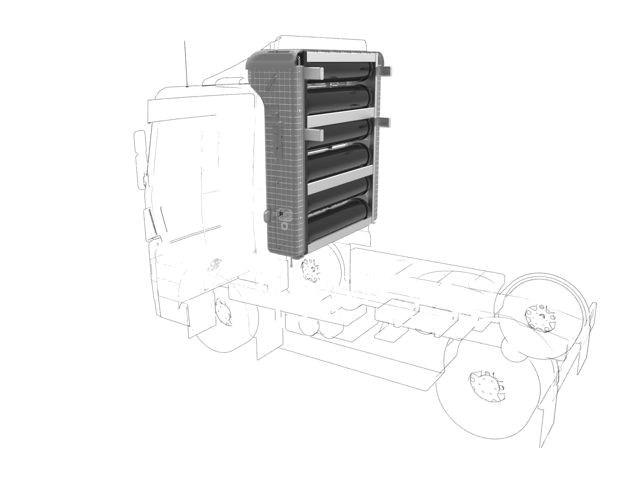

Order to cover 315 high-pressure hydrogen vessels to equip 45 trucks by the end of 2024, with developments in novel storage systems to extend truck range by almost 60%.

Photo Credit: Plastic Omnium

(Île-de-France, France) has announced a partnership with (Île-de-France), a mobility specialist decarbonizing heavy-vehicle fleets, through the integration of hydrogen storage systems. The first phase of the partnership covers an order of a total of 315 high-pressure hydrogen vessels to equip 45 trucks by the end of 2024 — Plastic Omnium’s tanks are Type IV tanks (carbon fiber-wrapped shells with a plastic liner). The partners also plan to work together to develop new hydrogen storage systems that will increase truck ranges to more than 750 kilometers (~466 miles), an uplift of almost 60%.

“We are delighted that Hyliko has chosen our storage systems to leverage the development of highly specialized solutions for decarbonizing heavy vehicle fleets,” Marc Perraudin, CEO of Plastic Omnium New Energies, says. “This announcement is further proof of the existence of a buoyant market for hydrogen mobility in the commercial transportation sector.”

Hyliko provides transporters and logistics operators with an all-in-one solution, combining leasing and maintaining hydrogen-powered trucks, supplying hydrogen produced from biomass residues and managing the fleets’ carbon footprint. By 2030, Hyliko aims to avoid the emission of 1.5 million tons of CO2, to equip 10% of the European hydrogen truck market (around 15,000 vehicles) and to deploy 100 hydrogen production and storage stations in Europe.

Plastic Omnium says it has pioneered hydrogen mobility since 2015. Its New Energies division develops and produces comprehensive hydrogen systems for all forms of mobility, ranging from storage to management system, including fuel cell modules.

“The partnership will also mean we can boost the operational performance of our vehicles,” Florent Bergeret, chairman and founder of Hyliko, adds.

Related Content

-

Braided thermoplastic composite H2 tanks with co-consolidated molded boss areas to fit EV battery space

BRYSON project demonstrates possible designs, automated manufacturing and low permeability concepts, including EVOH liner and novel PPA matrix.

-

Composites end markets: New space (2025)

Composite materials — with their unmatched strength-to-weight ratio, durability in extreme environments and design versatility — are at the heart of innovations in satellites, propulsion systems and lunar exploration vehicles, propelling the space economy toward a $1.8 trillion future.

-

Update: THOR project for industrialized, recyclable thermoplastic composite tanks for hydrogen storage

A look into the tape/liner materials, LATW/recycling processes, design software and new equipment toward commercialization of Type 4.5 tanks.