Norco joins defense and security compliance register

The Joint Supply Chain Accreditation Register (JOSCAR) is a collaborative tool used by the aerospace, defense and security industry to act as a single repository for pre-qualification and compliance information.

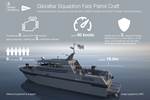

Photo Credit: Norco

Norco (Dorset, Poole, U.K.), manufacturer of large glass fiber-reinforced polymer (GFRP) structures, announced in August that it has joined the Joint Supply Chain Accreditation Register (JOSCAR), a collaborative tool used by the aerospace, defense and security industry to act as a single repository for pre-qualification and compliance information. According to Norco, the system was established following an initiative led by ADS Group and includes a growing number of prime contractors as registered buyers such as The Ministry of Defence, BAE Systems (Farnborough, U.K.) and Rolls Royce (Derby, U.K.).

By holding common supplier details in a central system, Norco says, information can to be accessed by all participating buying organizations, reducing duplication, time, resources and cost and giving wider market access.

“I am very pleased that the company has received JOSCAR certification," says Mark Northey, the managing director at Norco. "It is testament to the hard work and commitment of the team here at Norco. To be invited into JOSCAR gives us the opportunity to tender for contracts with key buyers in the defense industry that were previously unattainable.”

With JOSCAR accreditation, Norco says it demonstrates it is “fit for business” in the aerospace, defense and security sectors while reducing third party risk in the supply chain.

Related Content

-

Near-zero erosion ultra-high temperature CMC

K3RX commercializes UHTCMC for a wide range of markets, demonstrating performance in prototypes, assemblies and advancing manufacturing to reduce cost.

-

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

-

Industrializing additive manufacturing in the defense/aerospace sector

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.