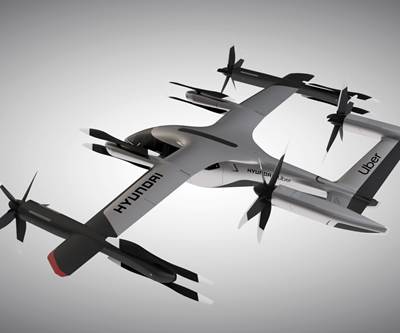

Hyundai Motor, Supernal unveil eVTOL vehicle cabin concept

Concept details — such as CFRTP material incorporation, a biomimetic design and a focus on safety — provide a first look at how Hyundai integrate its mobility capabilities to develop commercial urban, regional air vehicles.

Photo Credit, all images: Supernal, Hyundai Motor Group

(Washington, D.C., U.S.) has revealed its initial electric vertical takeoff and landing (eVTOL) vehicle cabin concept, — comprising composite materials, amongst others — providing the first look at how (Seoul, South Korea) is integrating automotive capabilities to develop the advanced air mobility (AAM) market.

Supernal partnered with Hyundai’s design studios to create the cabin concept as it worked to certify its eVTOL vehicle for commercial use in the U.S. starting in 2028 — and in the E.U. and U.K. shortly after. Beyond the vehicle, Supernal is collaborating with external partners and Hyundai’s more than 50 affiliates spanning automobiles, automotive parts, construction, robotics and autonomous driving to responsibly co-create the expansive AAM value chain.

“In order for AAM to become a wide-spread mode of transportation, every detail — from the passenger experience to regulations and infrastructure — needs to be addressed from the start and work in lockstep with one another,” Jaiwon Shin, president of Hyundai Motor Group and CEO of Supernal, says. “Supernal is partnering with Hyundai Motor Group’s top automotive designers to develop our eVTOL vehicle for manufacturability and widespread public acceptance. We are taking the time to create a safe, lightweight commercial eVTOL that provides our future passengers with the security and comfort they find in their own cars.”

Supernal’s provides clues to how the company is harnessing automotive design processes and materials — while meeting commercial aviation’s highest safety standards — to optimize the AAM passenger experience and price-point. The design embodies biomimicry — a butterfly in this case — and the company’s pillars of safety, human-centered design and environmental responsibility.

With sustainability as a priority, the cabin concept incorporates materials such as advanced recyclable carbon fiber-reinforced thermoplastic (CFRTP), durable plant-based leather, recycled plastic fabric and responsibly sourced woods. The seat frame uses excess raw material from the airframe manufacturing process.

Front view of the vehicle.

The team of engineers and designers used the automotive industry’s reductive design approach to create the lightweight interior cabin, which is made of forged carbon fiber. Ergonomically contoured seats are said to offer a cocoon-like environment for passengers. Deployable seat consoles mimic automobile center consoles and provide a charging station and stowage compartment for personal items. Grab handles built into the cabin doors and seatbacks assist with ingress and egress. A combination of lighting — including overhead lights inspired by automobile sunroofs — adjusts with the various stages of flight to emulate a “light therapy” effect. The cabin layout draws on automotive space innovation with a minimized bulkhead, which enables generous headroom and package functionalities.

Hyundai says it is is leveraging its expansive mobility and mobility-enabling capabilities to develop a family of electric air vehicles. Complementing U.S.-based Supernal’s battery-powered eVTOL vehicle designed for intracity passenger journeys starting in 2028, Hyundai’s Korea-based division, focused on regional air mobility, is developing a hydrogen-powered mid-sized vehicle for regional — city-to-city — cargo and passenger journeys. The division plans to launch service of its hydrogen vehicle in the 2030s.

Supernal and the division are partnering with Hyundai’s manufacturing innovation teams across the globe to create a robust high-rate, high-quality AAM manufacturing process that will reportedly produce electric air vehicles at scale — at an increasingly affordable price-point — over the coming decades.

“Hyundai Motor Group is working to leverage synergies between automotive's high-rate manufacturing capabilities and aerospace’s high certification standards to build the foundation for everyday use of passenger and cargo air vehicles,” Shin concludes.

Related Content

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

Read MoreAssembling the Multifunctional Fuselage Demonstrator: The final welds

Building the all-thermoplastic composite fuselage demonstrator comes to an end with continuous ultrasonic welding of the RH longitudinal fuselage joint and resistance welding for coupling of the fuselage frames across the upper and lower halves.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreRead Next

Hyundai Motor Co., Uber unveil air taxi model

At the Consumer Electronics Show (CES), the companies announced an aerial ridesharing partnership and a new eVTOL design.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read More